The main performance characteristics:

1. Steel-welded construction, vibration to eliminate stress, with high strength and good rigidity.

2. Hydualic top-drive, steadiness and reliability. Mechanical stop, steel torsion bar maintain synchronization, high precision.

3. Motorize-adjustinf device of backgauge and rams stroke, fine adjusting by handwheel, numberical display.

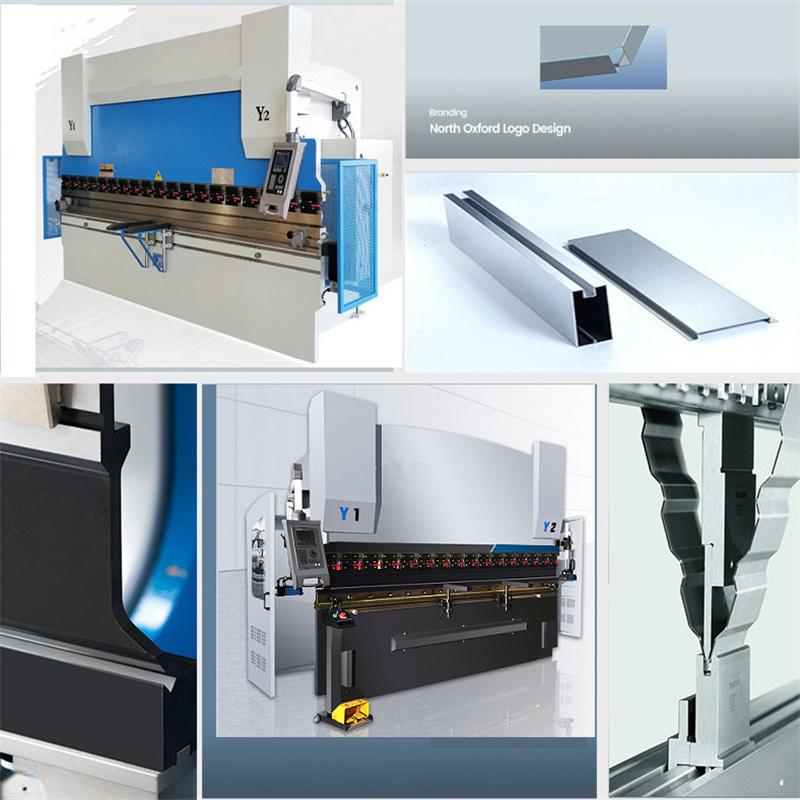

HYDRAULIC PRESS BRAKE

1. Adopt integrated hydraulic control system, more reliable and easy for maintenance.main hydraulic valves from Bosch (Germany)

2. All pipes, flange and joint with vibrations proof and leakage proof design and setting .

3. Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly.

4. The hydraulic system is made in compliance with current regulations.

ELECTRICAL SYSTEM

1. Electrical Cabinet under theinternational Standard, safe and reliable, strong anti interference capability.

2. Protective fence to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate

SYNCHRO CONTROL SYSTEM

1. Patented system for exact parallelism and a high repeat accuracy

2. The worktable adopts the particular design,reducing the crowning distortion amount of lower tool effectively.

3. Adopt steel torsion bar synchro system,simple in structure and high in accuracy,ensures theparallelism between beams is used for the synchronism.

| Model | Nominal force | table length | Distance between columns | Throat depth | Slider stroke | Maximum opening height between worktable and slider | Main motor power | Machine tool size (L x W x H) | Machine weight |

| Units | kn | mm | mm | mm | mm | mm | kw | mm | kg |

| 63/3200 | 630 | 3200 | 2700 | 250 | 100 | 400 | 5.5 | 4340×1460×2420 | 6000 |

| 100/3200 | 1000 | 3200 | 2700 | 320 | 150 | 450 | 7.5 | 3450×1450×2600 | 8000 |

| 160/3200 | 1600 | 3200 | 2700 | 320 | 200 | 465 | 11 | 3250×2535×2920 | 13000 |

| 250/3200 | 2500 | 3200 | 2700 | 400 | 250 | 560 | 15 | 4000×2250×4060 | 18400 |

| 250/4000 | 2500 | 4000 | 3300 | 400 | 250 | 560 | 15 | 4800×2250×4060 | 20000 |

| 250/5000 | 2500 | 5000 | 4100 | 400 | 250 | 560 | 15 | 5800×2250×4060 | 22000 |

| 250/7000 | 2500 | 7000 | 6250 | 400 | 250 | 560 | 15 | 7800×2250×4160 | 25000 |

| 320/4000 | 3200 | 4000 | 3300 | 400 | 250 | 560 | 22 | 4060×2570×4560 | 22000 |

| 320/5000 | 3200 | 5000 | 4300 | 400 | 250 | 560 | 22 | 5060×2570×4560 | 24510 |

| 320/6000 | 3200 | 6000 | 5300 | 400 | 250 | 560 | 22 | 6060×2570×4560 | 27020 |

| 400/4000 | 4000 | 4000 | 3100 | 400 | 320 | 625 | 37 | 4050×3240×3880 | 29950 |

| 400/5000 | 4000 | 5000 | 4210 | 400 | 320 | 625 | 37 | 5050×3240×3880 | 37000 |

| 400/6000 | 4000 | 6000 | 5100 | 400 | 320 | 625 | 37 | 6050×3240×3880 | 44050 |

| 500/4000 | 5000 | 4000 | 3100 | 400 | 320 | 630 | 37 | 4090×2965×5320 | 32700 |

| 500/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5090×2965×5320 | 39750 |

| 500/6000 | 5000 | 6000 | 5100 | 400 | 320 | 630 | 37 | 6090×2965×5320 | 46800 |

| 630/5000 | 6300 | 5000 | 4100 | 400 | 320 | 710 | 45 | 5050×4910×3200 | 67950 |

| 630/6000 | 6300 | 6000 | 5100 | 400 | 320 | 710 | 45 | 6050×4910×3200 | 75000 |

| 800/5000 | 8000 | 8000 | 6700 | 350 | 400 | 750 | 55 | 9500×3000×6050 | 100000 |

FAQ

1: How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines, such as CNC Lathe Machine, CNC Milling Machine,Vertical Machining Center, Lathe Machines, Drilling Machine, Radial Drilling Machine, Sawing Machine, Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Anui Province, China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

Details

- Slider Stroke (mm): 200 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 200 mm

- Machine Type: Synchronized, Press Brake

- Length of Working Table (mm): 1600 mm

- Width of Working Table (mm): 200 mm

- Condition: New

- Material / Metal Processed: Carbon steel

- Automation: Automatic

- Extra Services: Machining

- Weight (KG): 1230

- Motor Power (kw): 3 kw

- Key Selling Points: Competitive Price

- Warranty: 1 Year, 1 Year

- Applicable Industries: Manufacturing Plant

- Showroom Location: Indonesia, Russia, UAE

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 13 months

- Core Components: Motor

- Product name: WC67K Hydraulic press brake machine price cnc press brake

- Raw Material: Sheet / Plate Rolling

- Material: Processed: Alloy/Aluminum/Stainless

- Keywords: press brake ; press brake tooling

- Nominal force:: 1000kn

- Usage: Metal Sheet Rolling Cutting Bending

- Application: Carbon Steel

- Certification: ce

- After-sales Service Provided: Video technical support, Online support

- After Warranty Service: Video technical support, Online support