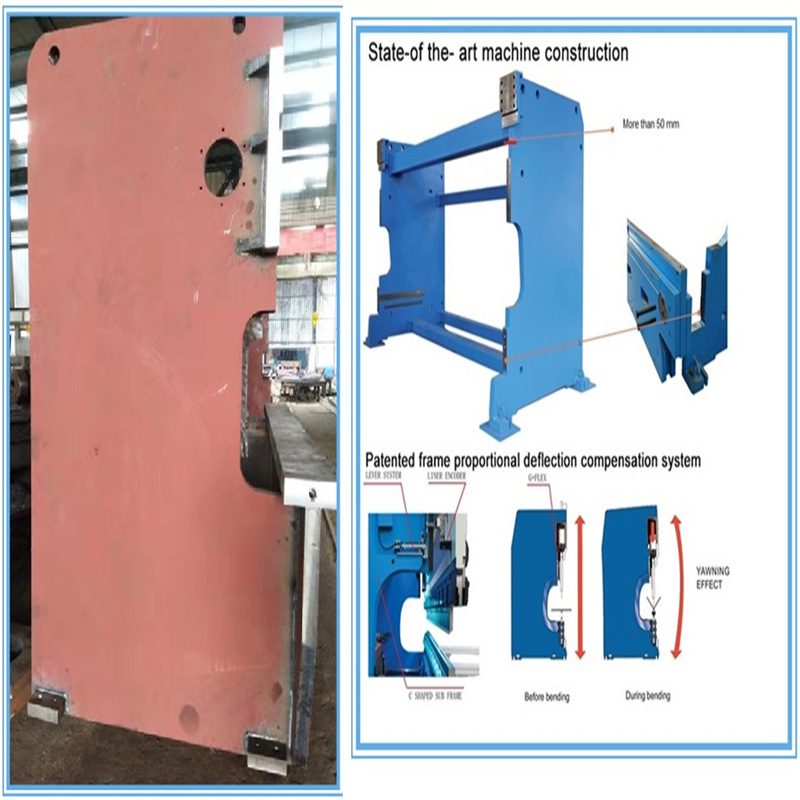

A machine that presses workpieces into different shapes according to requirements and bends thin plates. It is an important equipment for bending workpieces in the sheet metal industry. The bending machine is composed of a worktable part, a sliding block part, a back gauge part, an oil cylinder part and so on.

Parameters and specifications

| Seri-al NO. | Name | Unit | Remark /Number | |

| 1 | Nominal Pressure | KN | ||

| 2 | Worktable Length | mm | ||

| 3 | Poles Distance | |||

| 4 | Throat Depth | |||

| 5 | Slider Travel | |||

| 6 | Slider Travel Adjustment | |||

| 7 | The max. Opening height between worktable and slider | |||

| 8 | Oil Cylinder diameter | |||

| 9 | The max.work pressure of the hydraulic system | Mpa | ||

| 10 | Speed of the slide stroke | Full Load-speed | mm/sec | |

| Work-speed | ||||

| High-return speed | BS | |||

| 11 | Main Motor | Type | ||

| Power | KW | |||

| Rotate Speed | R/min | |||

| 12 | Slide stroke adjustment motor | Type | ||

| Power | KW | |||

| Rotate Speed | R/min | |||

| 13 | Back-gauge adjustment motor | Type | ||

| Power | KW | |||

| Rotate Speed | R/min | |||

| 14 | Steering Pump | Type | ||

| Power | Ml/r | |||

| Rotate Speed | Mpa | |||

| 15 | Overall dimension | Length | MM | |

| Width | ||||

| Height | ||||

| 16 | Power requirement | 380V (-15%,+15%) 50Hz ,3PH | ||

Controller System:

- 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17″ high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the controllers multitasking environment

- Sensor bending & correction interface

- Profile-TL offline software

Oil Pump: Sunny From USA Amazing low noise, made of high strength cast iron and unique design for inner noise reduction, Low sensitivity to oil pollution and assure of long service life

Hydraulic System: Our press brake machine uses Hoerbiger integrated hydraulic control system that make it more reliable and easy for maintenance.

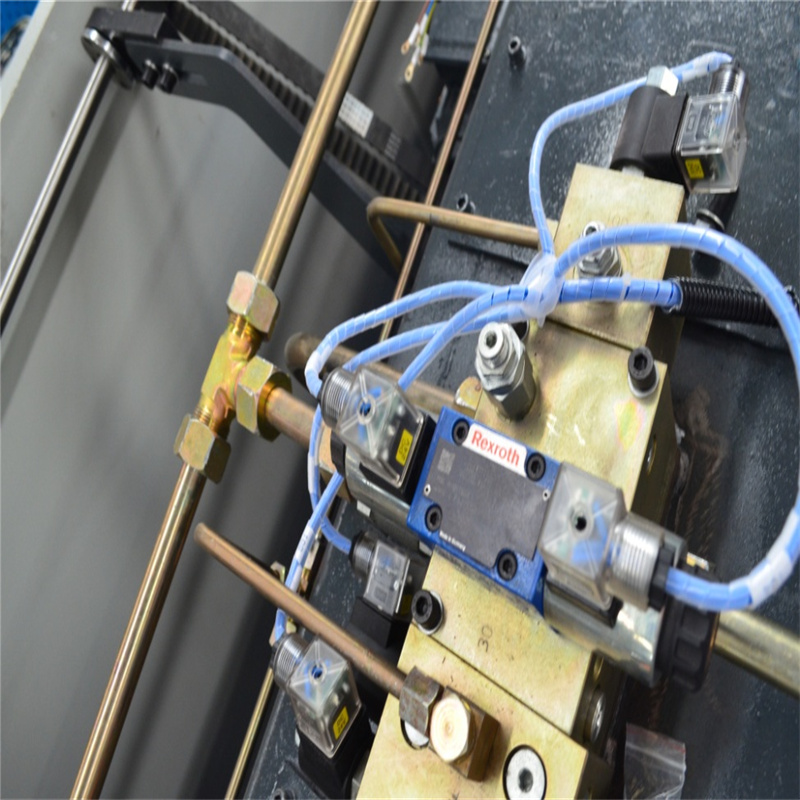

Germany Valve: Adopt Germany's Bosch Rexroth integrated structure of oil pump and hydraulic valve to ensure the bending accuracy.

Electrical System: Our press brake adopt Schneider electrical components. The high quality electric parts can make the machine performing well even the electricity is not stable and customers can easily get the replacement anywhere in the world.

Fast Clamp: The standard equipped fast clamp will help you replace the top punch in very short time. Convenient and time-saving. Fast intermediate loading and unloading function to improve work efficiency.

Upper Punch And Down Die: The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use. Material and HRC47 degree values are marked on it.

Main Motor: Compared to traditional stepper motors, the advantages of using servo motors include: improve the accuracy to ±0.01mm, the noise decrease to 25 decibels, reduce energy consumption by 60%, consump 70% less hydraulic oil and 30% higher efficiency.

Back Gauge: We using the Taiwan PMI ball screw and linear guide to ensure the moving of X-axis with higher accuracy than using rod. And the backgauge adopt timing belt & wheel mechanism which controlled by servo motor instead of step motor. The height of the backgauge finger can be adjusted manually. Totally there're THREE pcs of backgauge fingers for positioning.

Front Support Arm: Our standard front support arm is 180° adjustable. Adopted with two Linear to keep the heavy duty plate working

FAQ

Q1: Are you a factory or a trading company?

A: RAYMAX is committed to the R&D ,production and sales of CNC Press Brake ,Shearing Machine, Rolling Machine,Fiber Laser Cutting Machine especially for high power laser cutting machine.

Q2: How about the shipping fees?

A:Please kindly tell us your nearest port or address with postcode.Exactly freight we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Q3: What if we don't know how to operate your machine?

A:We will send video and English manual with the machine.If you still have some doubts ,We can talk by whatsapp or skype and e-mail.

Q4: How do you guarantee your quality?

A: RAYMAX have more than 15 years of manufacturing experience,our machines have got the European CE approval,and exported to Europe as many other countries and regions around the world.

Details

- Slider Stroke (mm): 100 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 250 mm

- Machine Type: Synchronized, Press Brake

- Length of Working Table (mm): 1600

- Width of Working Table (mm): 140 mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless Steel, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: Machining

- Weight (KG): 2750

- Motor Power (kw): 7.5 kw

- Key Selling Points: Multifunctional

- Warranty: 5 years

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Energy & Mining

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 5 years

- Core Components: Bearing, Motor, Pump, Gear

- Product name: CNC Hydraulic Press Brake

- Material: Mild Steel Stainless Steel Aluminum

- Power: 7.5 KW

- Application: Stainless Plate Bending

- Hydraulic System: Bosch Rexroth Germany

- Function: Metal Press Break

- Keyword: Hydraulic Press Break

- Cutting material: Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

- Name: WC67K CNC Press brake