1. Overall welded and processed structure.

1. Overall welded and processed structure.

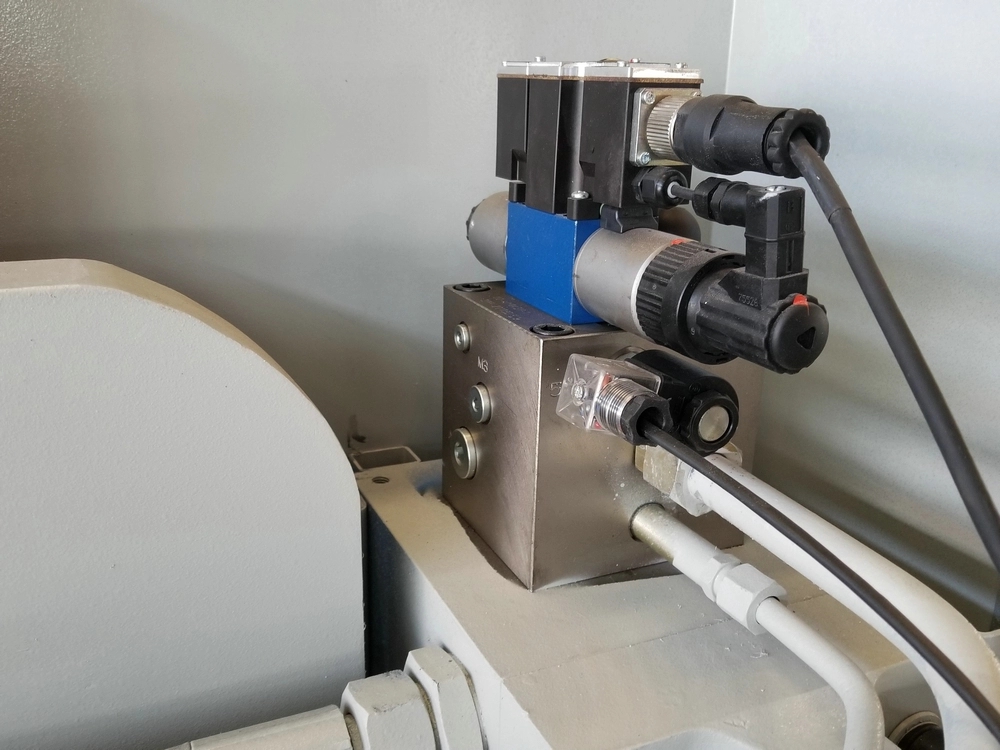

2. Closed loop control mode composed of electric-hydraulic servo valve and measure ruler.Ensure the highest control precision,

bending accuracy and repositioning accuracy are also reach to the highest level.

3. Back gauge mechanism can be multi-axes controlled.

4. Integrated hydraulic system decreases the pipe connections, oil leakage, and increases the stability and overall beautifies.

5. Worktable equipped with hydraulic and mechanical compensation to avoid the deformed upper beam from affecting the quality of the work piece, it is automatically adjusted by the CNC controller with convenient and accuracy.

6. CNC controller normally uses Holland DELEM, Italy ESA, Swiss CYBELEC, all with multi-languages.

| Specification | Nominal Pressure (KN) | Length of working table (mm) | Distance up rights (mm) | Throat between depths (mm) | Ram stroke (mm) | Motor power (KW) |

| WC67Y40/2200 | 400 | 2200 | 1700 | 200 | 100 | 4 |

| WC67Y100/5000 | 1000 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y160/3200 | 1600 | 3200 | 2500 | 320 | 200 | 11 |

| WC67Y200/6000 | 2000 | 6000 | 4800 | 320 | 200 | 15 |

| WC67Y700/7000 | 7000 | 7000 | 5600 | 400 | 300 | 45 |

Synchronized block

Synchronized block

Servo proportional valve plays a synchronous role, so that the slide at both ends of the consistent decline, so the servo CNC bending machine biasing capacity is strong.

Mold selectionAny mold can be customized according to customer requirements. The standard mold angle is 90°, non-standard molds need to be customized, and the upper mold can be segmented.

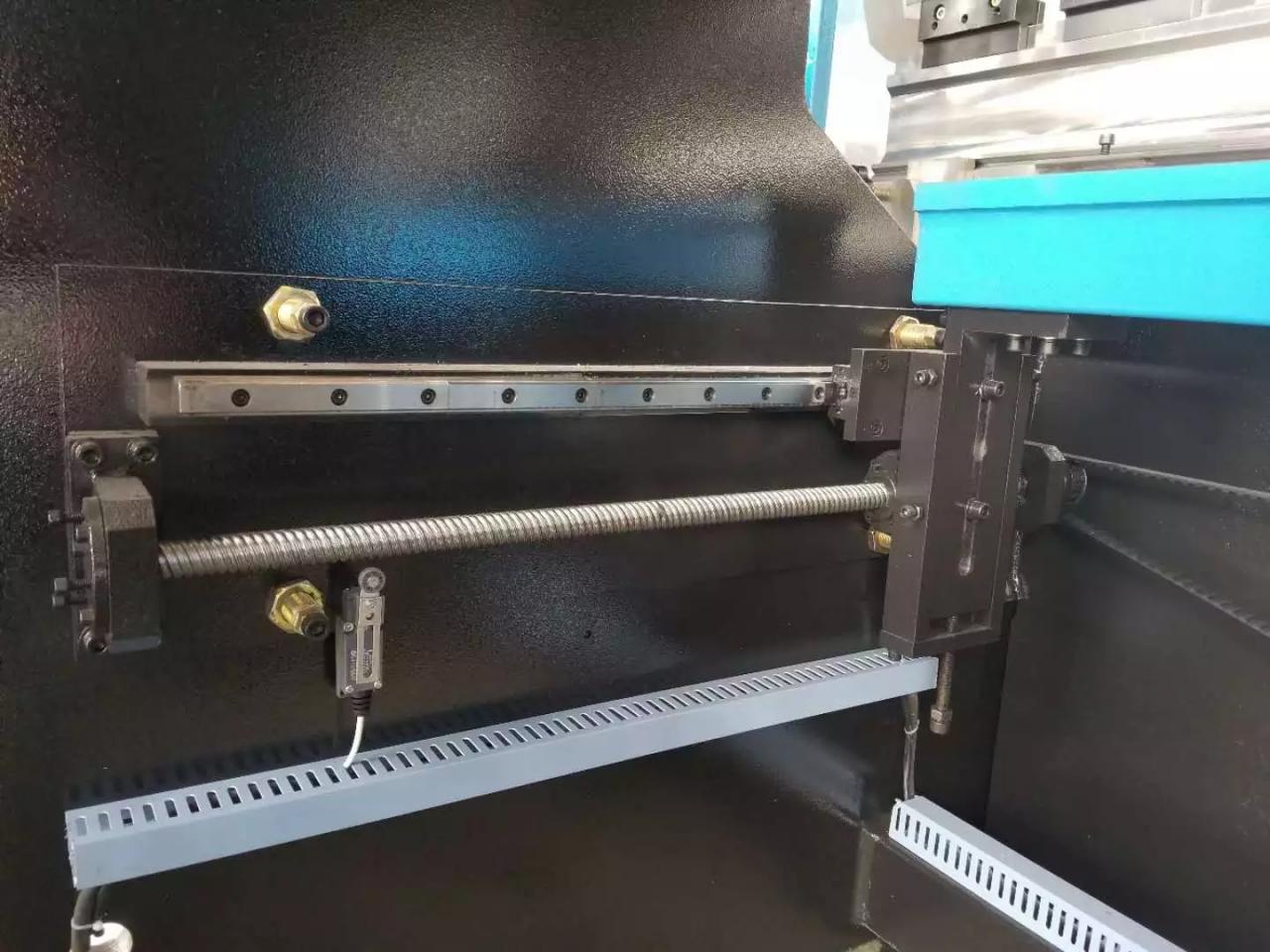

Hydarulic Press Brake Ball Screw Linear Guide with Synchronous Belt

Hydarulic Press Brake Ball Screw Linear Guide with Synchronous Belt

●High Precision Backgauge is equipped with fine ball screw and guide linear

●Backgauge adopts horizontal installation shell structure with high stability,singe shell double guide rail, high precision, X-axixs drive, automatioc CNC sytem

FAQ

1. Production time: 20-40 days according to different type.

2. Installation and commissioning time: 10-15 days.

3. Installation and commissioning issue: We will send 1-2 technicians to help with machine installation and commissioning, customer pays for their tickets, hotel and diet.

4. Warranty time: 12 months from date of commissioning completion, but no more than 18 months from date of delivery.

5. Payment term: 30% as prepayment, balance 70% before delivery or L/C at sight.

6. We supply full english documents: including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc.

Details

- Slider Stroke (mm): 260 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 20006000 mm

- Width of Working Table (mm): 1700 mm

- Dimension: 3200*1700*2700

- Condition: New

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Aluminum

- Automation: Automatic

- Extra Services: End Forming

- Weight (KG): 1700

- Motor Power (kw): 22 kw

- Key Selling Points: Automatic

- Warranty: 1 Year, 1 yeaer

- Applicable Industries: Building Material Shops

- Showroom Location: Canada, Indonesia, Russia

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel

- Certification:: ISO 9001:2000

- Color: As per customer's requirements

- Machine type: Press Brake Sheet Bending Machine

- Power: Hydraulic

- Function: bending

- System: Rexroth Germany

- Electric components: Schneider,Omran,Siemens

- Voltage: 110V/380V/415V

- Weight: 3000kgs

- Certification: ce

- After-sales Service Provided: Field installation, commissioning and training, Online support

- After Warranty Service: Field maintenance and repair service

- Local Service Location: Canada, Indonesia, Russia