Main functions and features

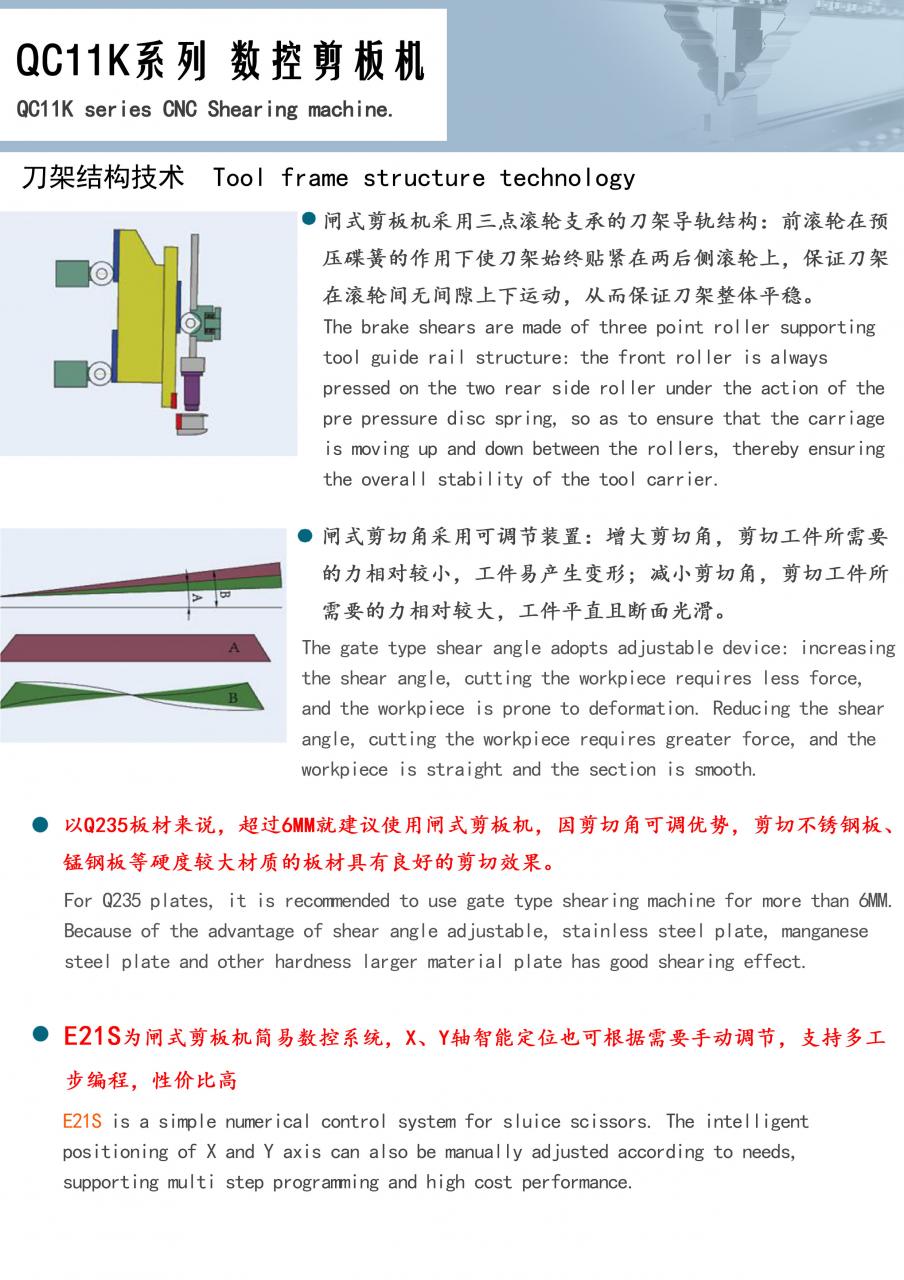

1. The second generation of shear.

2. Welded steel plate construction, heating to eliminate stress, with high strength and good rigidity.

3. Advanced integrated hydraulic system with and excellent reliabitity quality.

4. Rapidly,accurately and conveniently adjusting the blade clearance by motor

5. The adjustable rake angle can minimize plate deformation.

6. As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can be also guaranteed.

7. Shearing in sections, shadow-line cutting.

8. Counter for the motorized back gauge.

9. Back support device (optional).

| Model | Mild Steel (450MPA) | Cutting Length(mm) | Depth Of Throat(mm) | Back Gauge Range(mm) | Rake Angle Adjustment | Strokes Per Minute | Main Motor | L×W×H(mm) | Weight(t) |

| 4×2000 | 4 | 2000 | 80 | 750 | 0.5°~2° | 14 | 5.5 | 2600×1680×1750 | 3.8 |

| 4×2500 | 4 | 2000 | 80 | 750 | 0.5°~2° | 14 | 5.5 | 3125×1750×1765 | 4.5 |

| 6×2500 | 6 | 2500 | 80 | 750 | 0.5°~1°30′ | 14 | 7.5 | 3100×1725×1900 | 5.3 |

| 6×3200 | 6 | 3200 | 80 | 750 | 0.5°~1°30′ | 12 | 7.5 | 3935×1840×1995 | 6.5 |

| 6×4000 | 6 | 4000 | 80 | 750 | 0.5°~1°30′ | 10 | 7.5 | 4650×1840×2100 | 8.5 |

| 6×5000 | 6 | 5000 | 80 | 750 | 0.5°~1°30′ | 8 | 7.5 | 5650×2050×2400 | 10.5 |

| 6×6000 | 6 | 6000 | 80 | 750 | 0.5°~1°30′ | 8 | 7.5 | 6650×1980×2380 | 15.2 |

| 8×2500 | 8 | 6000 | 80 | 750 | 0.5°~1°30′ | 14 | 7.5 | 3135×1840×2075 | 6 |

| 8×3200 | 8 | 3200 | 80 | 750 | 0.5°~1°30′ | 12 | 7.5 | 3850×1990×2050 | 6.8 |

| 8×4000 | 8 | 4000 | 80 | 750 | 0.5°~1°30′ | 10 | 7.5 | 4650×1890×2075 | 9 |

| 8×5000 | 8 | 5000 | 80 | 750 | 0.5°~2° | 7 | 15 | 5650×2050×2400 | 12.5 |

| 8×6000 | 8 | 6000 | 100 | 750 | 0.5°~2° | 7 | 15 | 6805×2115×2715 | 19.8 |

| 10×2500 | 10 | 2500 | 100 | 750 | 0.5°~2°30′ | 10 | 15 | 3195×1915×2205 | 8 |

| 10×3200 | 10 | 3200 | 100 | 750 | 0.5°~2°30′ | 8 | 15 | 3895×1900×2235 | 8.8 |

| 10×4000 | 10 | 4000 | 100 | 750 | 0.5°~2°30′ | 6 | 15 | 4695×1970×2270 | 9.15 |

| 10×5000 | 10 | 5000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 5700×2115×2715 | 16 |

| 10×6000 | 10 | 6000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 6905×2115×2800 | 22 |

| 12×2500 | 12 | 2500 | 100 | 750 | 0.5°~2°30′ | 10 | 15 | 3195×2000×2210 | 8.3 |

| 12×3200 | 12 | 3200 | 100 | 750 | 0.5°~2°30′ | 8 | 15 | 3895×1950×2240 | 9.2 |

| 12×4000 | 12 | 4000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 4710×1950×2450 | 13 |

| 12×5000 | 12 | 5000 | 100 | 750 | 0.5°~2°30′ | 5 | 18.5 | 5750×2115×2800 | 20 |

| 12×6000 | 12 | 6000 | 100 | 750 | 0.5°~2°30′ | 5 | 18.5 | 7150×2300×3100 | 29 |

| 16×2500 | 16 | 2500 | 100 | 750 | 0.5°~2°30′ | 8 | 15 | 3215×1970×2340 | 8.7 |

| 16×3200 | 16 | 3200 | 100 | 750 | 0.5°~2°30′ | 7 | 15 | 3915×1970×2455 | 11 |

| 16×4000 | 16 | 4000 | 100 | 750 | 0.5°~2°30′ | 6 | 15 | 4715×2010×2590 | 15 |

| 16×5000 | 16 | 5000 | 100 | 750 | 0.5°~3° | 5 | 22 | 6000×2300×3000 | 23 |

| 16×6000 | 16 | 6000 | 80 | 750 | 0.5°~3° | 5 | 37 | 7250×2400×3100 | 36 |

| 20×2500 | 20 | 2500 | 100 | 750 | 0.5°~3° | 6 | 22 | 3235×2020×2465 | 10.5 |

| 20×3200 | 20 | 3200 | 120 | 750 | 0.5°~3° | 5 | 30 | 4150×2065×2755 | 18 |

| 20×4000 | 20 | 4000 | 120 | 750 | 0.5°~3° | 4 | 30 | 4955×2125×2885 | 21 |

| 20×5000 | 20 | 5000 | 120 | 750 | 0.5°~3° | 4 | 37 | 6000×2300×3050 | 29 |

| 25×2500 | 25 | 2500 | 120 | 750 | 0.5°~3.5° | 5 | 37 | 3465×2130×2710 | 15 |

| 25×3200 | 25 | 3200 | 120 | 750 | 0.5°~3.5° | 5 | 37 | 4120×2200×3000 | 21 |

| 25×4000 | 25 | 4000 | 120 | 750 | 0.5°~3.5° | 4 | 37 | 4950×2200×3150 | 26 |

| 30×2500 | 30 | 2500 | 120 | 750 | 0.5°~3.5° | 4 | 37 | 3465×2170×2770 | 16 |

| 30×3200 | 30 | 3200 | 120 | 750 | 1°~3.5° | 3 | 37 | 4200×2300×3200 | 23 |

| NO. | Item | Parameter | Unit |

| 1 | Cutting thickness | 16 | mm |

| 2 | Cutting Length | 6000 | mm |

| 3 | Backgauge Range | 20-1000 | mm |

| 4 | Material Strength | ≤450 | N/mm² |

| 5 | Shear Angle | 0.5-3 | ° |

| 6 | Strokes | ≥4 | (min-1 ) |

| 7 | Main motor power | 22 | KW |

| L | 7250 | mm | |

| 8 | Overall dimension W | 2400 | mm |

| H | 3100 | mm | |

| 9 | Machine weight | 35000 | kg |

Why Choose Us

Packing&Shipping

We have cooperated with experienced shipping forwarders for many years, they arrange the shipment. No matter by express, by airor by sea, we will track the course of the goods all the way, to make sure goods arrive at you on time and in good condition.

FAQ

1. What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3. Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4. Where are you? Can I visit you?

A: Sure, welcome to you visit our factory at any time.

5. How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6. What kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment, please contact me.

Details

- Place of Origin: Anhui, China

- Brand Name: RAYMAX

- Condition: New

- Type: Shearing Machines

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Marketing Type: Hot Product 2019

- Warranty of core components: 3 years

- Core Components: PLC, Engine, Bearing

- Voltage: 220V380V

- Rated Power: 7.5

- Dimension(L*W*H): 6750X1700X1500

- Year: 2020

- Warranty: 3 years

- Key Selling Points: Multifunctional

- Applicable Industries: Machinery Repair Shops

- Showroom Location: None

- Weight (KG): 11 KG

- style: Luxury

- Product name: guillotine shearing machine

- Machine Type: guillotine shearing machine

- Application: Construction Projects

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Online support

- After Warranty Service: Video technical support, Online support, Spare parts

- Local Service Location: None

- Certification: CE