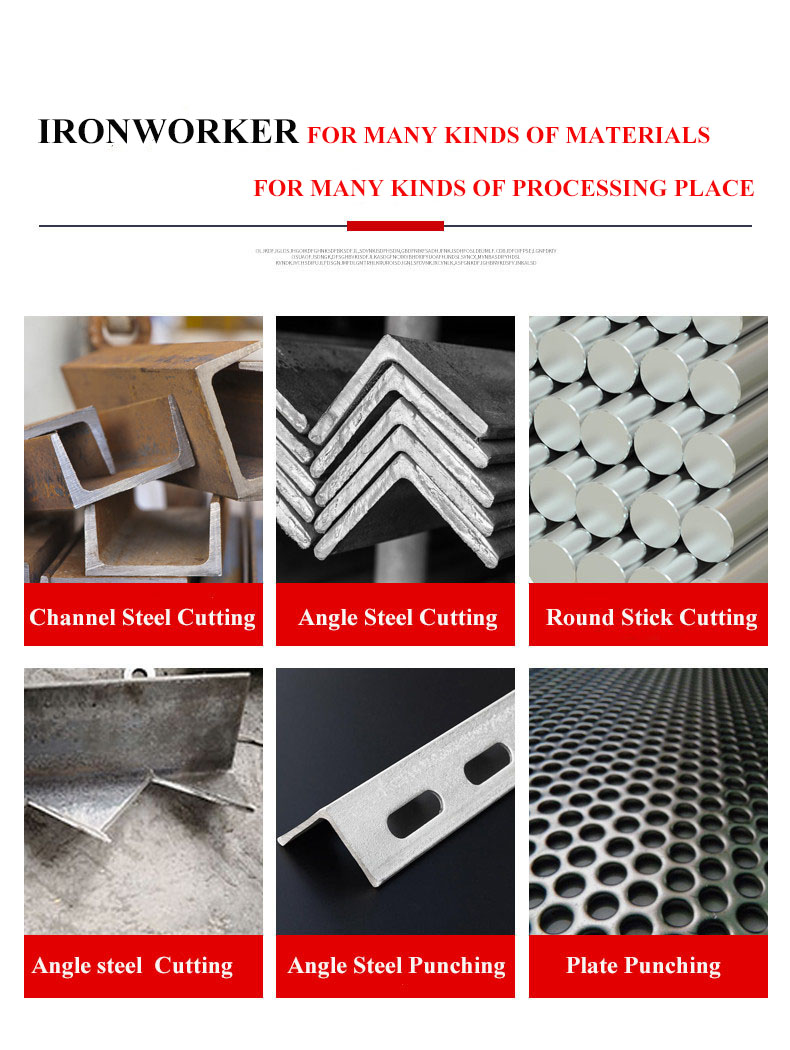

Products Description

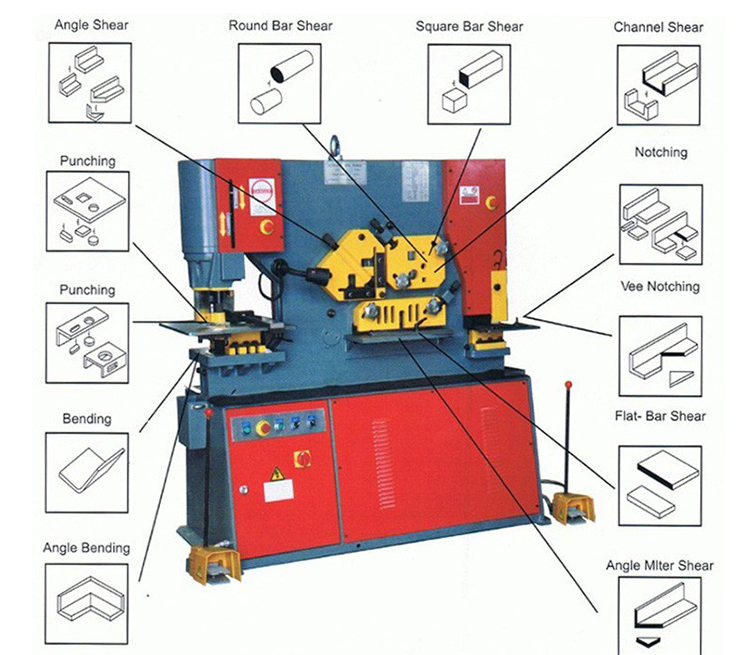

Its series of products are ideal equipment for cutting all kinds of angle steel, I-beam, U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible to finish series operations simultaneously on one machine, such as punching, shearing and notching, Dual-piston-type combined punching and shearing machine allows two-man operation at the same time (stamping another work station), German Rexroth’s integrated hydraulic valve block ensures the stability of the machine, Through Thermal Effect of annealing processing, the entire rack is able to keep its shape forever, without deformation. The introduction of imported brand accessories ensures the parts’ service life and use precision.

(1) Punching: effective punching can be achieved with the machine, and stamping die is easy to be replaced.

(2) Bar cutting: you can quickly cut the round bar and square steel, if you want to cut U-shaped, I-beam or T-profile section steel only by exchanging the cutting blade and the operation procedure is very simple.

(3) Angle cutting: you can cut several 90 ° and 45 ° angles with the help of special dies.

(4) Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work by making the bending moulds.

(5) Notching: The machine is equipped with a large-shaped slotting blade head, which can meet your general use, as to, special shaping blade head can be customized.

Details Images

Product Paramenters

| Standard Components | ||

| 1 | Electrical components | Schneider Electrical from French |

| 2 | Main Motor | Siemens from Germany Brand |

| 3 | 2 independent hydraulic cylinders | Anhui Wuyang, top in China |

| 5 | Backguage | manual adjustment |

| 6 | Foot switch | 2 independent switches |

| 7 | Hydraulic System | Bosch-Rexroth form Germany |

| 8 | Gear pump | Shanghai Hangfa,top in China |

| 9 | Sealing rings | NOK, Janpa |

| 10 | working stations | 5pcs |

| Optional Components | ||

| 1 | Punching machine | Movable work light |

| 2 | hydraulic system overload protection | ■Yes □No |

| 3 | Motor overload protection | ■Yes □No |

| 4 | customised blade & toolings | ■Yes □No |

| 5 | Safety standards | ■CE □CSA □NR-12 □OSHA |

Packing up to shipping standard

1. Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2. All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3. The outmost is wooden case with fixed formwork.

4. The bottom of the wooden case has firm iron jack, convenient to handing and transport.

FAQ

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2. What is the average lead time?

For samples, the lead time is about 10 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4. What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6. How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Details

- CNC or Not: Normal

- Condition: New

- Nominal Force (kN): 1200

- Power Source: Hydraulic

- Year: 2022

- Voltage: 440V 280V 220V optional

- Dimension(L*W*H): 2355*960*2090mm

- Motor Power (kW): 7.5

- Weight (T): 4

- Key Selling Points: Easy to Operate

- Warranty: 1 Year

- Showroom Location: Russia

- Applicable Industries: Energy & Mining, Advertising Company, Machinery Repair Shops, Building Material Shops

- Product name: Ironworker

- Oil Seal: NOK

- Color: Optional Color

- pump: sunny

- Cutting Material: Metal Stainless Steel Carbon Steel

- function: bending/punching/shearing/notching/cutting

- Hydraulic System: Germen BOSCH

- Advantage: multi-function

- After-sales Service Provided: Online support, Video technical support, Field installation, commissioning and training

- After Warranty Service: Video technical support, Field maintenance and repair service, Spare parts, Online support

- Local Service Location: Russia

- Certification: ISO9000