Products Description

(1) The whole EU streamlined design, heat treatment rack, high rigidity worktable, optional mechanical compensation device, to achieve precision bending.

(2) Hydraulic synchronous control and NC or CNC programmable logic controller ensure accurate repeatability and ease use.

(3) Integrated hydraulic system (Bosch Rexroth Germany) allows automatically switch to slow bends in a quick way.

(4) X axis , Y axis , Z axis ,R axis and V axis realize accurate positioning function by frequency converter through NC or CNC system programming control.

(5) Cutting-edge frequency response hydraulic control technology, more stable machine tools, more reliable operation.

(6) The best ratio of parameters, optimal core configuration ensure stable performance, more convenient operation.

Details Images

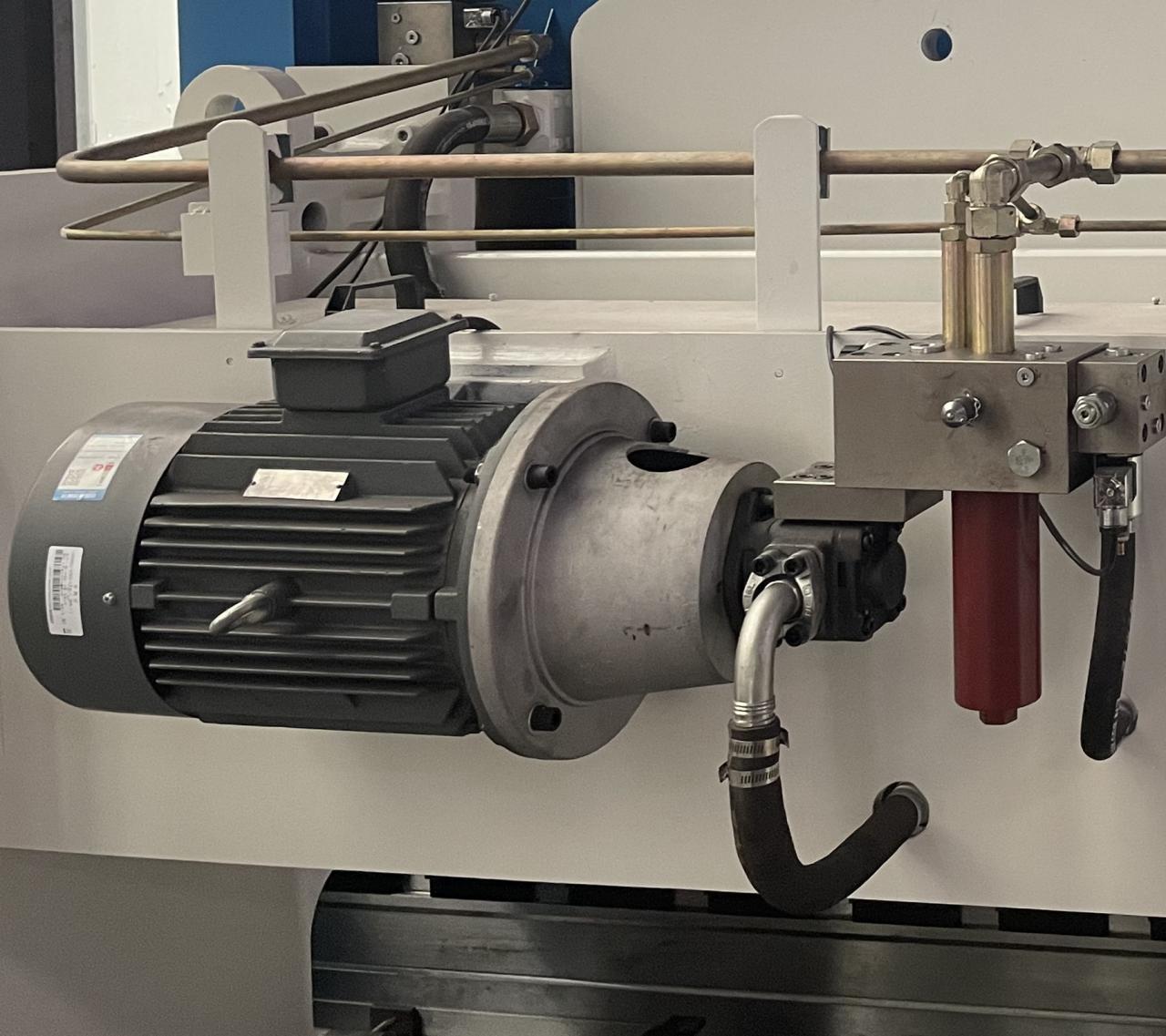

Siemens main motor

Using siements motor to ensure the machine service life and lower the working nosie.

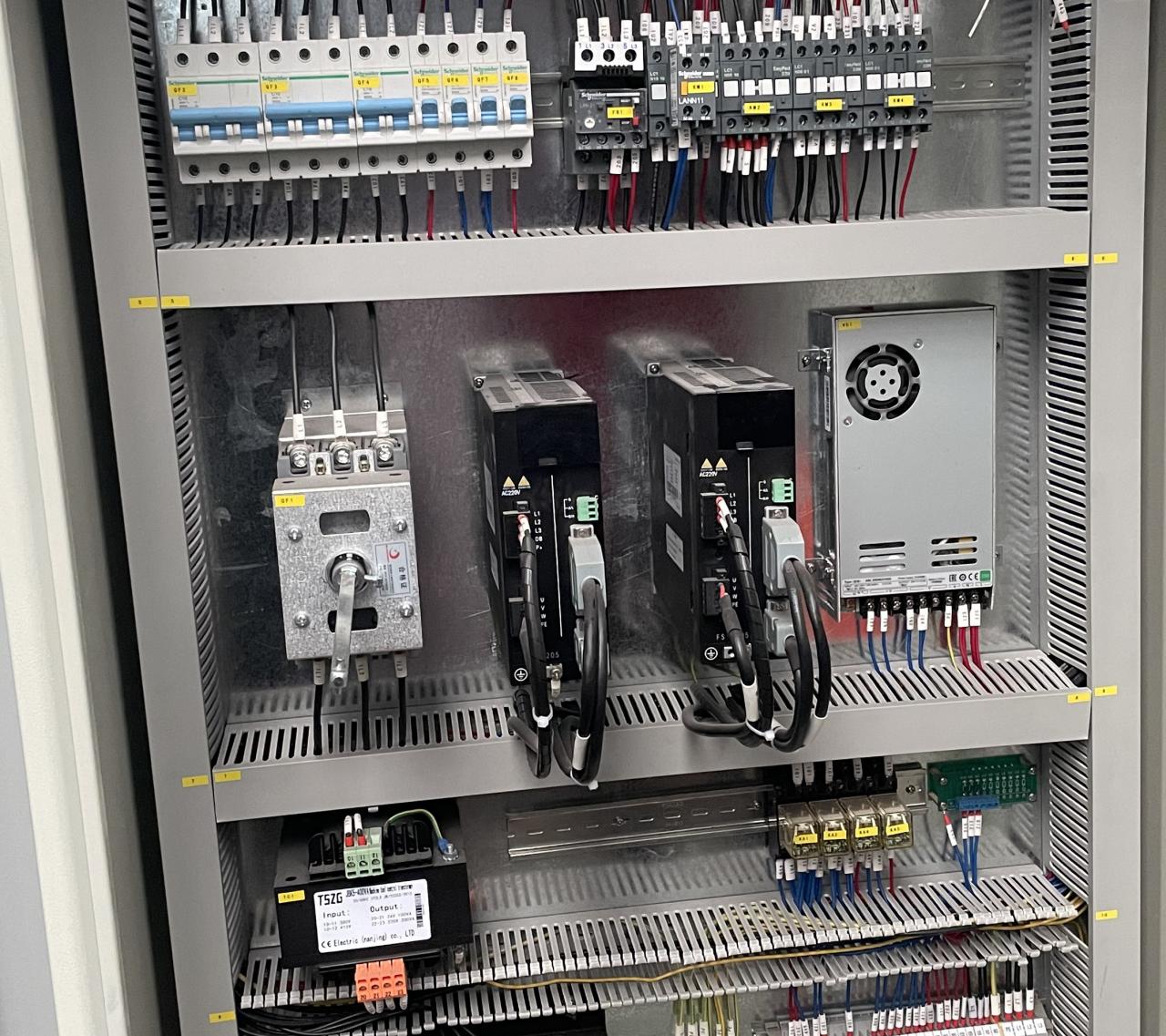

France Schneider electric

Using the Schneider electric with high reliability and Estun servo drive to improving the positioning accuracy of X.Y Axis.

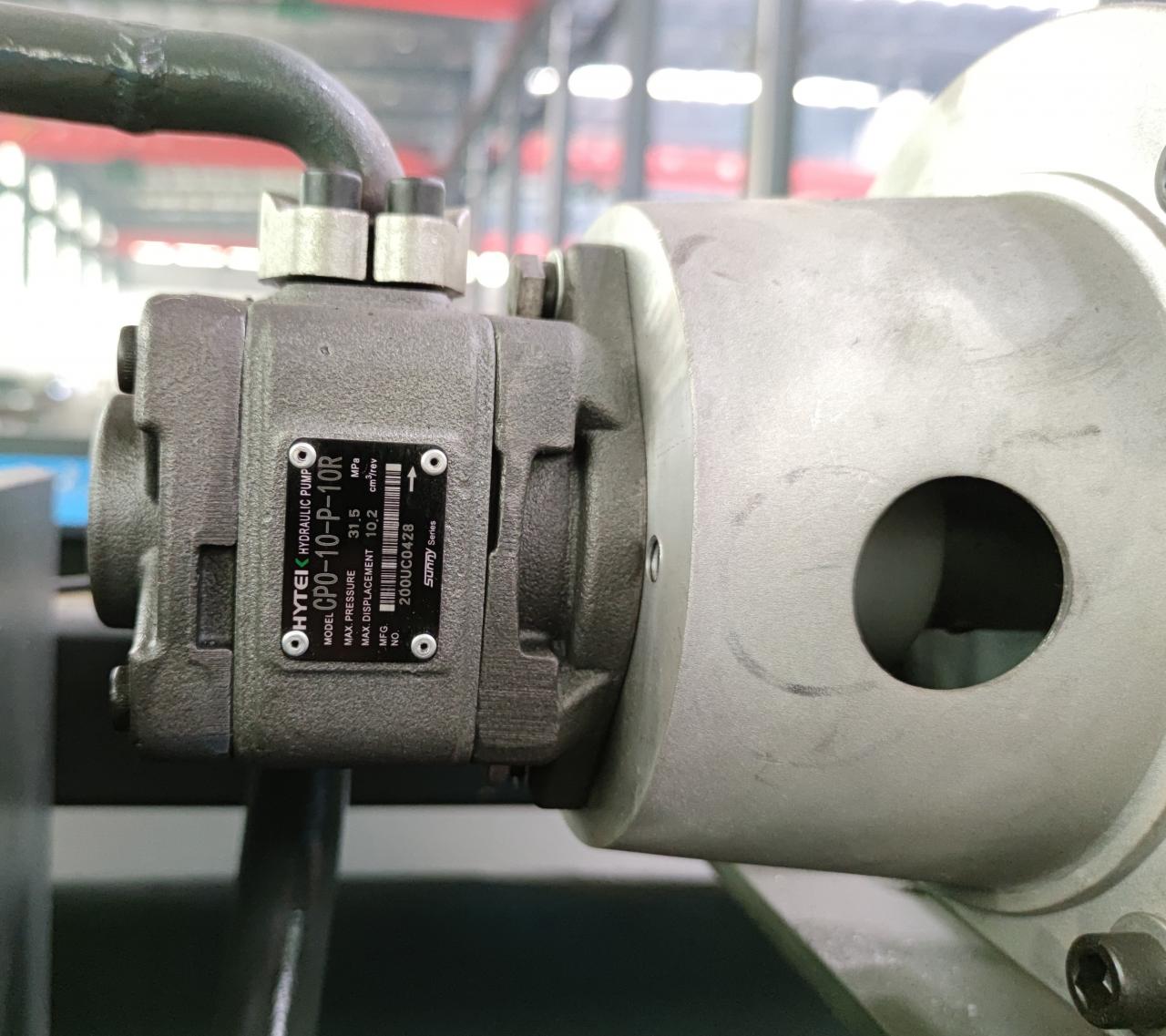

USA SUNNY oil pump

Using USA SUNNY oil pump to ensure the pump service life and lower the working noise

Fast-clamp

Mechanical quick clamps or upper die is more safe and efficient when changing the upper die.

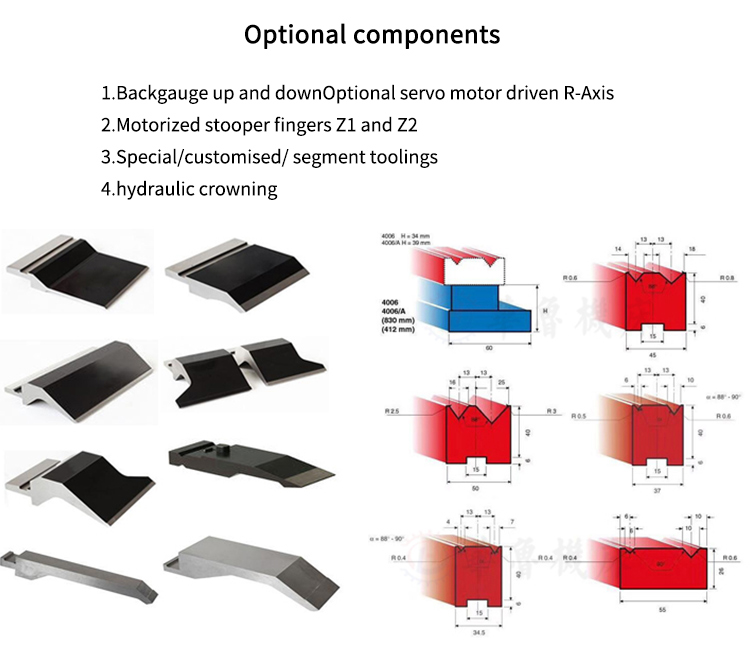

Press brake tooling and the crowning

Front supporter

Front supporter, simple structure,with powerful function, supporting up/down adjustment,and can move along T-shaped channel or the linear guide railin horizontal direction.

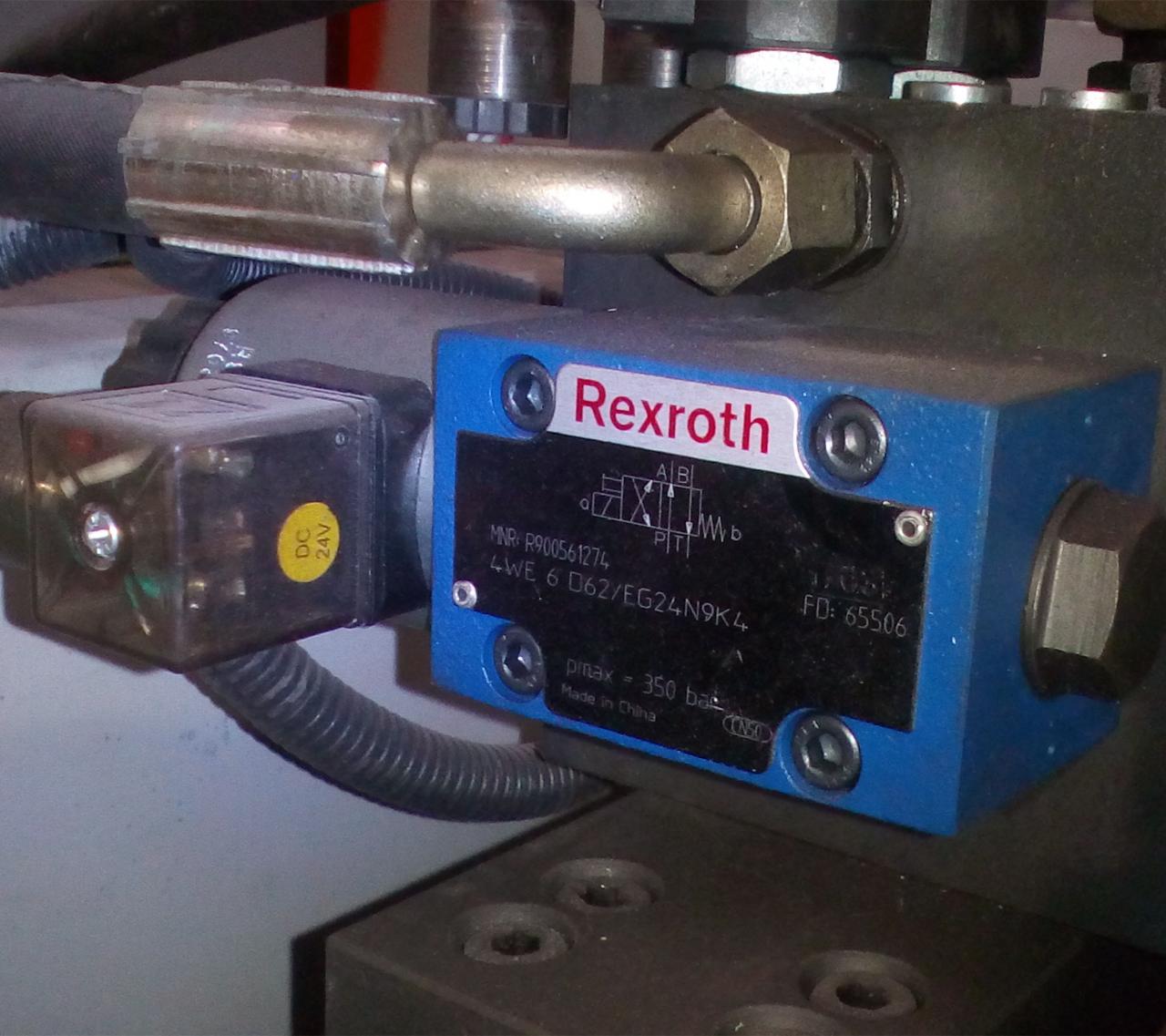

HYDRAULIC SYSTEM

■ Pipe Connection: * All pipe connection using the EMB from Germany Brand.

■ Hydraulic System: * Adopt integrated hydraulic control system, more reliable &easy for maintenance. The hydraulic system is the from Bosch - Rexroth, Germany.

Backgauge

* High-precision backgauge device, ball screw and linear guider rail

* Equipped with light-sensitive limit switch, improving limit accuracy.

* It is driven by steep motor and inverter with high positioning accuracy, unique designed synchronous transmission mechanism, reliable and stable

Product Paramenters

Standard configuration

| Main configuration list | ||

| 1 | NC Control system | E21 E300 DA41 DA53S DA56S DA66T DA69T |

| 2 | Electrical components | Schneider Electrical from French |

| 3 | Main Motor | Siemens from Germany Brand |

| 4 | BackGauge & RAM Drive | Inverter from Taiwan delta |

| 5 | Travel switch | Schneider Electrical from French |

| 6 | Foot switch | KACON from South Korea |

| 7 | Hydraulic System | Bosch-Rexroth form Germany |

| 8 | Hydraulic Pump | SUUNY or SAEMP form Taiwan |

| 9 | Sealing Element | PARKER from U.S.A Brand |

| 10 | Tubing connector | EMB form Germany Brand |

| 11 | Ball screw/ Polished rod | HIWIN from TaiWan Brand |

| Safety Configuration | ||

| 1 | Warning of high oil temperature | ■Yes □No |

| 2 | High oil pressure protection | ■Yes □No |

| 3 | Motor overload protection | ■Yes □No |

| 4 | Oil inlet filter jammed warning | ■Yes □No |

| 5 | Laser Safety Protection | □Yes ■No |

| 6 | Left & Right side protection | ■Yes □No |

| 7 | Electricity leakage protection | ■Yes □No |

| 8 | Safety Relay | □Yes ■No |

| 9 | Monitoring and Redundant valves | □Yes ■No |

| 10 | Safety standards | ■CE □CSA □NR-12 □OSHA |

Our service

| Pre-service: |

| 1. We will help you confirm the model of our machine according to the working capacity |

| 2. Very welcome to see our product how to work in the factory before you place an order with us. |

| 3. Provide sample and design plan for some product. |

| Aftersales-service: |

| 1. Free installation, trial start and adjustment, training. |

| 2. You can come to RAYMAX factory for training. We will offer professional guide. Direct and effective face-to-face training. |

| 3. Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service. |

Packing up to shipping standard

1. Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2. All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3. The outmost is wooden case with fixed formwork.

4. The bottom of the wooden case has firm iron jack, convenient to handing and transport.

FAQ

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2. What is the average lead time?

For samples, the lead time is about 10 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4. What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6. How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Details

- Slider Stroke (mm): 150 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 320 mm

- Machine Type: bending machine

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 250 mm

- Dimension: 4000mm*1600mm*2600mm

- Condition: New

- Place of Origin: China

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum, Plastic, PVC

- Automation: Automatic

- Extra Services: Machining

- Year: 2021

- Weight (KG): 8500

- Motor Power (kw): 7.5 kw

- Key Selling Points: Automatic

- Warranty: 1 Year

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining, Advertising Company, Other

- Showroom Location: Russia

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox, Other

- Function: Steel Metal Bending

- Voltage: 220V/380V/415V/440V/customized

- Hydraulic System: Bosch Rexroth Germany

- Electrical components: Schneider Electrical

- Bending thickness: 8mm

- Ball screw/ Polished rod: HIWIN TAIWAN

- pump: sunny

- Color: Optional

- Main Motor: Siemens Germany Brand

- Control system: E21/DElEM/CYBELEC

- Certification: ISO 9001:2000

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service