Features

Adhering to advanced design concept, simple appearance, comfortable operation human-machine experience

Special NC or CNC bending control system is fitted with mainframe of the bending machine.

Multi-work-step programming function is able to achieve an automatic operation and contnuous positioning of multi-step procedures,as well as an automatic precision adjustment for positions of back gauge stopper and gliding block.

The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of positions of stopper and gliding block, as well as procedures and parameters.

IMported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear Stopper, for proceSssing precision of machine to be higher.

Details Images

Optional Controller

Delem DA-50 Touch Series

The DA-50 Touch series press brake controls offer modern compact and versatile solutions for powerful economic press brake applications.

Graphical programming and numerical programming solutions based on state-of-the-art press brake control enable optimal flexibility.

Optional DA-60 Touch series

Cybelec CybTouch 8,12,15,Switzerland

CybTouch is specifically designed for CNC press brakes.

It has an intuitive and vivid color full touch screen and a high integration of functions. Its robust design is available in panel or housing version.Thanks to its large keys, online help, simplified software and many other automatic functions that constantly guide the operator,

CybTouch open architecture concept for customer specific functionality assurance. User friendly programming with ease due to the “intuitive programming” concept.

Esautomotion S630,S640,S650 ,Italy

The intelligent heart of software specifically designed for bending is beating in all our VIS-600 and 800 CNCs, thus guaranteeing exceptional performance with every type of processing.

Developed ad-hoc according each client’s needs, our turn key software allows both 2D and 3D visualization, while optimizing all the bending sequences.

Thanks to unique Esautomotion’s exclusive FLED (Fast LEearning Design) philosophy, it greatly simplifies and speed up the machineoperator’s work.

Stable Electrical

Cabinet Durable France Schneider electrics ensure the stable operation of the machine.Reasonable line connection and arrangement greatly reduces the failure rate. And the operator and all parts of the machine played a good protection.

Servo and drive to improve the positioning accuracy of X,R Axis

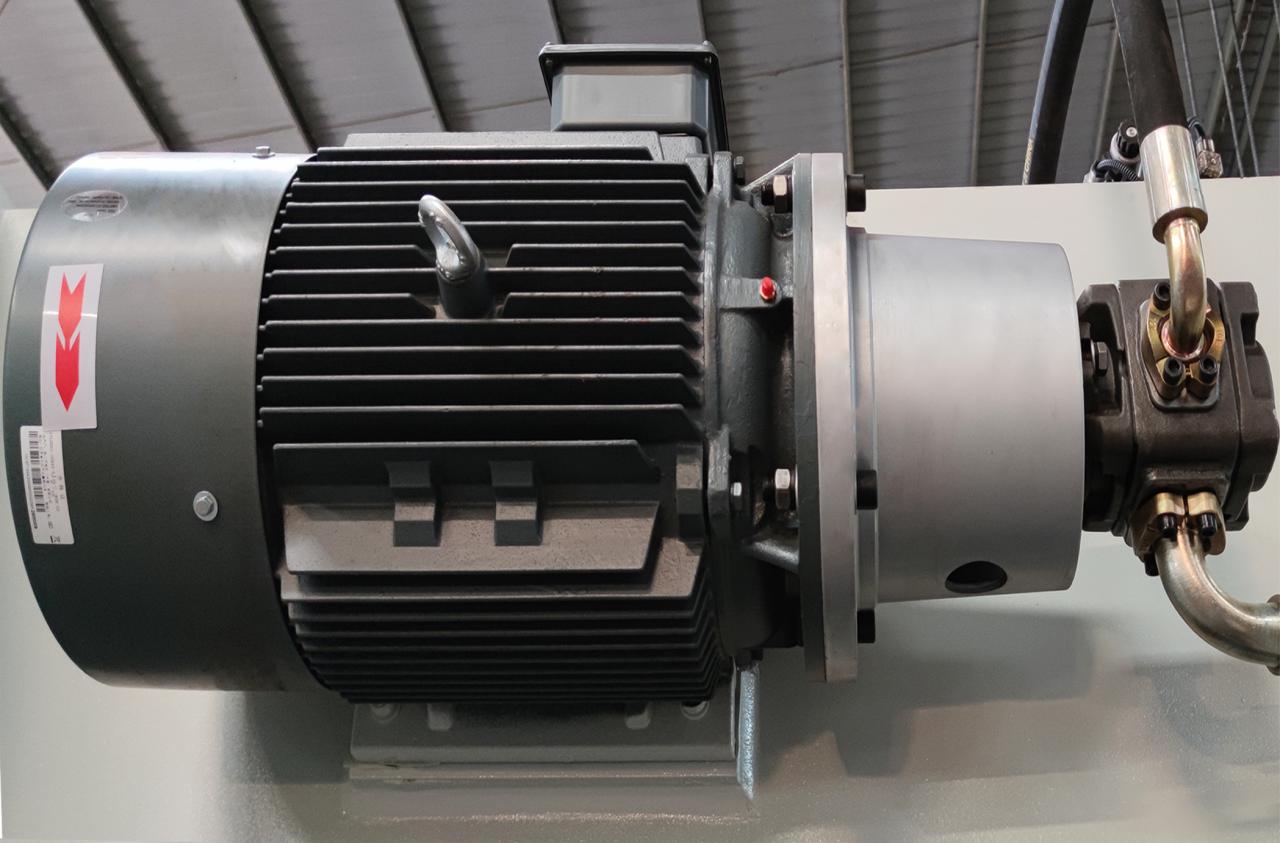

Superior Hydraulic System

Integrated hydraulic system, quick response. The low failure rate makes the machine run safely, efficiently and stably.The whole series of standard is equipped with galvanized cold drawn pipe and German ferrule type pipe joint. Reduce the risk of oil leakage by 50% compared with rubber and welded seamless tubing. And in can be longer service life.

High Precision Back-Gauge

The unique and novel ball screw linear guide structure back-gauge ensures high positioning accuracy. Multi-level with movable, adjustable stop fingers. Increased positioning range makes bending more efficient and accurate. Optional function more Complete multiple Axes.

Low Noise Power System

Using Germany Siemens main motor and USA SUNNY gear oil pump guarantee the machine service life and improve the machine working stability.At the same time, the special coupling device also greatly reduces the noise of the machine in the process of running.

Patent Fast Clamps

The whole series adopts RAYMAX GNSP standard fast holders. Patented rear butterfly hold down device,which can adapt to different types of European-standard, Amada type punches. Compared with the traditional tool holder, it can save more time and improve production efficiency.Safety, anti falling.There are also one button release upgrade style. Automatic hydraulic and pneumatic clamping are optional.

Diverse Press Brake Tools

Optimized design can make bending more simple and efficient. 42CrMo or C45 high frequency quenching process press brake tools, it is durable. Special surface nitriding treatment can be selected to prevent rust and beautiful appearance. Special punch and vdies can be customized according to the workpiece, and RAYMAX provide a complete set of solutions.

Dedicated Foot Switch

South Korea KACON pedal switch, improving the service life and operational sensitivity. With emergency stop, up and down control division. Make machine operating safer and easier.It can also be equipped with multi-functional rocker Z1, Z2-axis, R-axis manual control.

Optional Installation

*Oil Cooling Unit

*Light Curtain

*Laser Protection

*Front Auto Follow support

*Bending Robots

Size Chart of Design

| Type | Nominal force(mm) | Woektable length(mm) | Poles distance(mm) | Throat depth(mm) |

| WC67K-40T/1250 | 400 | 1250 | 1000 | 220 |

| WC67K-40T/1600 | 400 | 1600 | 1200 | 220 |

| WC67K-40T/2500 | 400 | 2500 | 1800 | 220 |

| Back-gaugeRange(mm) | Ram Strokes(mm) | Max open(mm) | Power(kw) | DimensionL*W*H(mm) |

| 10-500 | 100 | 320 | 4 | 1700*1550*2050 |

| 10-500 | 100 | 320 | 4 | 2100*1650*2050 |

| 10-500 | 100 | 320 | 5.5 | 2700*1750*2150 |

FAQ

Q1. How about your machine quality?

A1: Our machines distribute worldwide to about 50 counties where there are metal plate ind ustry ,there are Brilliant machines And where there are our machines,there are good reputation and terminal user satisfaction.

Q2: You are the manufacturer or trading comparly?

A2: We are the 100% manufacturer with more than 20 years manufacturing experience.

Q3. How about your after-sale service?

A3: 1. Technical solutions: we can provide technical solutions within one day.

2. Online video: Show you machine working video in factory . ( update every week)

3. Installation service: This is available with all of our machines,live video can be provided. We can also dispatch technician to customer's factory for installation machines. (Customers only need to pay for the airfare and hotel expense.)

4. Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality guarantee: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate: we will reply your questions within 12 hours.

Details

- Slider Stroke (mm): 220 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Synchronized, CNC Hydraulic Press Brake

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 1950 mm

- Dimension: 4800*1950*2800

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: Machining

- Year: 2021

- Weight (KG): 12000

- Motor Power (kw): 11 kw

- Key Selling Points: Competitive Price

- Warranty: 2 years

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining

- Showroom Location: Egypt, Turkey, United States

- Marketing Type: Hot Product 2021

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Bearing, Motor, Pump, Gear, PLC

- Control system: DA69T DA66T DA58T CT8 CT12

- Bending length: 4000mm

- Motor: Siemens Motor

- Servo motor Servo drive: INOVANCE OR ESTUN

- Power: 11 KW

- After-sales Service Provided: Video technical support

- Raw Material: Sheet Metal Plate

- Color: Customer Choose

- Seal Ring: NOK Japan