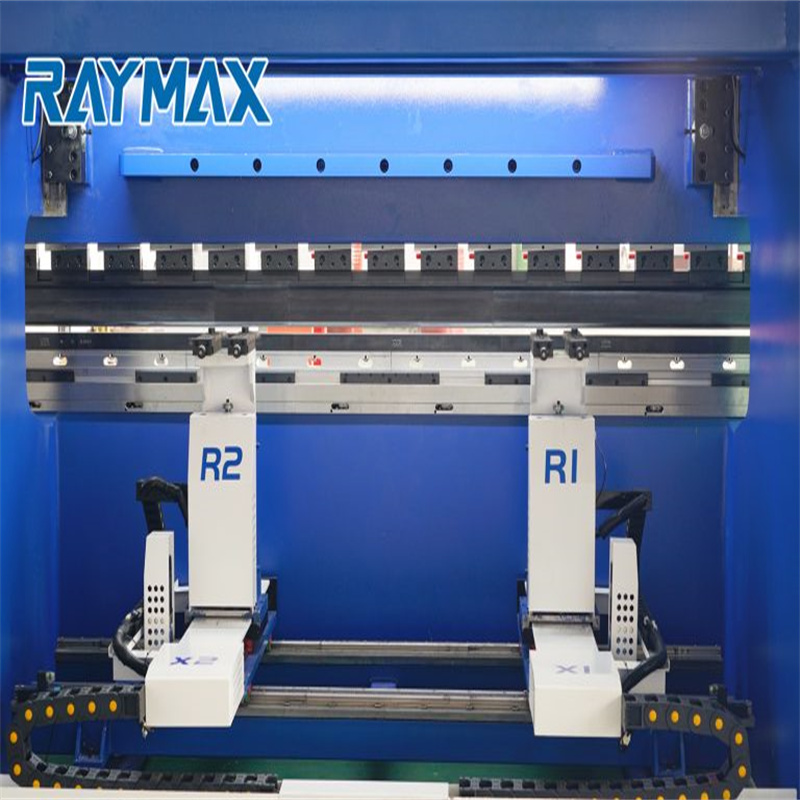

Cnc Metal Plate Electo-Hydraulic Press Brake For Sale

This Series press brake features an CNC crowning system for improved quality, a servo driven back gauge system for increased speeds, and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased working speeds, stroke, daylight, and pressing capacities of GENIUS Series machines. The future - as a result of rising energy costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

PRODUCT SPECIFICATIONS

| Type | 63T/2500 | 80T/3200 | 100T/3200 | 160T/3200 | 200T/3200 | 250T/3200 | 300T/3200 |

| Nominal Force (KN) | 630 | 800 | 1000 | 1600 | 2000 | 2500 | 3000 |

| Bending Length (mm) | 2500 | 3200 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Vertical Distance (mm) | 1900 | 2700 | 2700 | 2700 | 2700 | 2700 | 2700 |

| Depth of Throat (mm) | 350 | 350 | 400 | 400 | 400 | 400 | 400 |

| Slider Travel (mm) | 170 | 170 | 200 | 200 | 200 | 200 | 200 |

| Max.Opening (mm) | 380 | 380 | 420 | 420 | 420 | 420 | 420 |

| Main Power (Kw) | 5.5 | 7.5 | 7.5 | 11 | 15 | 15 | 22 |

| Crowing Cylinders | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| Control Axes | 3+1 | 3+1 | 3+1 | 3+1 | 3+1 | 3+1 | 3+1 |

| x Axis Travel(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| X Axis Speed (mm/s) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Overal Dimension (LxWxH)(mm) | 3100x1450x2050 | 3500x1550x2100 | 3500x1580x2400 | 3500x1650 x2500 | 3500x1680 x2550 | 3500x1700 x2600 | 3500x1800 x2730 |

| Weight(Ton) | 5.8 | 7.8 | 8.5 | 11 | 14.2 | 15.6 | 16.8 |

PRODUCT CONFIGURATION

DA-53T control system

*"Hot-key”touch navigation

*10.1" high resolution colour TFT

*Up to 4 axes (Y1,Y2 + 2 aux. axes)

*Crowning control

*Tool / material / product library

*Servo and frequency inverter control

*Advanced Y-axis control algorithms for

*closed-loop as well as open-loop valves.

*TandemLink (option)

*USB memory stick interfacing

*Profile-T offline software

Fast Clampings

*Standard double-V lower dies with different size and various shaped slots for choice , convenient for exchanging dies , capable for bending regular plates ,with high cost performance-ratio CNC double-V die workbench , convenient for installation of segmented dies .

Spain FAGOR Grating ruler

*Slider position signal is feedbacked to controller by Spain FAGOR Grating ruler , then the CNC controller adjusts the amount of fuel tank by changing the synchronous valve opening size , hereby controling the slider (Y1 ,Y2)running on the same frequency , maintaining the parallel state of the worktable.

Powerful Cabinet

*French schneider electrics to ensure machine stability , and Estun servo drive to control the accuracy of X, Y axes .

*Open Door Power Off

42CrMo Toolings

*The dies are made by 42CrMo steel ,hardness after heat treatment up to 42 degrees,ensuring the die service life

Siemens motor

*Guarantees the machine service life ,and reduce the noise when working

Oil pump

*American world famous brand forhydraulic pump. It performs well andprovides great power for the wholesystem. Using Sunny pump ensures thepump service life and lower workingnoise.

V- -axis Mechanical Crowing

*V-axis mechanical crowing, improving the accuracy of bending angle and linearity

Foot Switch

*It is movable and can stop the operation anytime you want by emergency button. Enchancing the service life and optional sensitiviy. It is more reliable.

Manual back gauge finger

*2 to 5 back gauge fingers (standard 3)

Taiwan HIWIN Ball Screw And Linear Guide Rail

*Equipped with Taiwan HIWIN ball screw and linear guide rail, backgauge adopts horizontal installation shell structure with high stability, single shell double guide rail, high precision, X axis drive, automatic CNC system

Details

- Slider Stroke (mm): 200 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 320 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 3250

- Width of Working Table (mm): 200 mm

- Dimension: 3250x1950x2800mm

- Condition: New

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: bend counting function

- Year: 2020

- Weight (KG): 11000

- Motor Power (kw): 15 kw

- Key Selling Points: Multifunctional

- Warranty: 2 years

- Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Restaurant, Construction works , Energy & Mining

- Showroom Location: None

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Motor, PLC

- Name: Hydraulic CNC Press Brake Machine Price 200Ton 4000 CT-8

- Keyword: Hydraulic CNC Press Brake Machine Price 200Ton

- Function: Steel Metal Bending

- Nominal Pressure (kN): 2000

- Certification: CE ISO

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

- After Warranty Service: Video technical support, Spare parts, Field maintenance and repair service

- Local Service Location: None