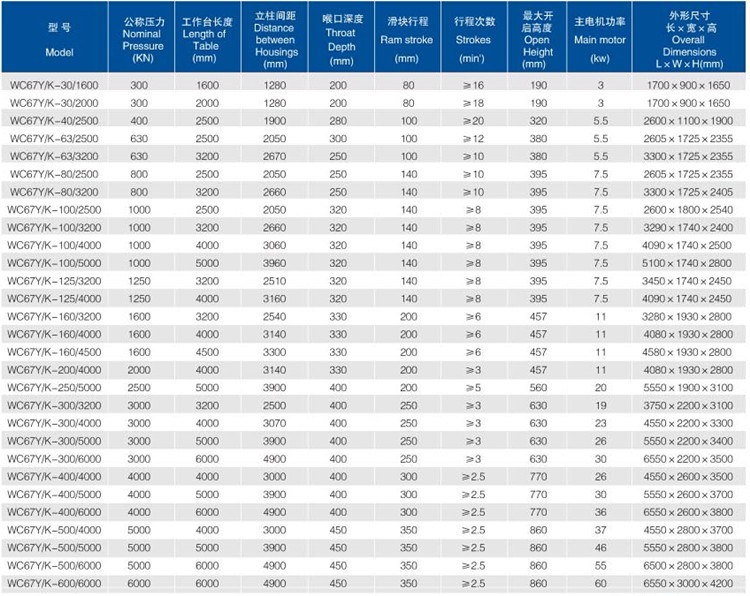

Products Description

1. Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating toeliminate stress, high strength and good rigidity.

2. Mechanical torque system makes sure the synchronization of cylinders.

3. The stroke of slider and back gauge is adjusted automatically by double servo motors or transducer, and showed on CNC Mechanical torque or NC control panel.

4. Slanting wedges can be chosen to install on the top dies which can be adjusted by hands or automatically. Hydraulic compensation system is installed under the worktable.

DA53T controller features:

- “Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1,Y2 2 axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB memory stick interfacing

- Profile-T offline software solution

Details Images

Germany Rexroth Hydraulic system

1)Integrated control system imported from Germany;

2)Decrease the installation of pipelines;

3)Ensure the working stability and better appearance.

Back gauge

1)Imported functional components to ensure the stopping precision.

2)More functional multi-axis blocking is available according to customer's requirement.

Germany Siemens motor

1) Closed loop control mode:Germany electro-hydraulic servo valve and imported grating ruler;

2) Totally different from traditional mechanical stop bending machines;

3) High precision of the glide position and bending;4)Accurate and stable operation.

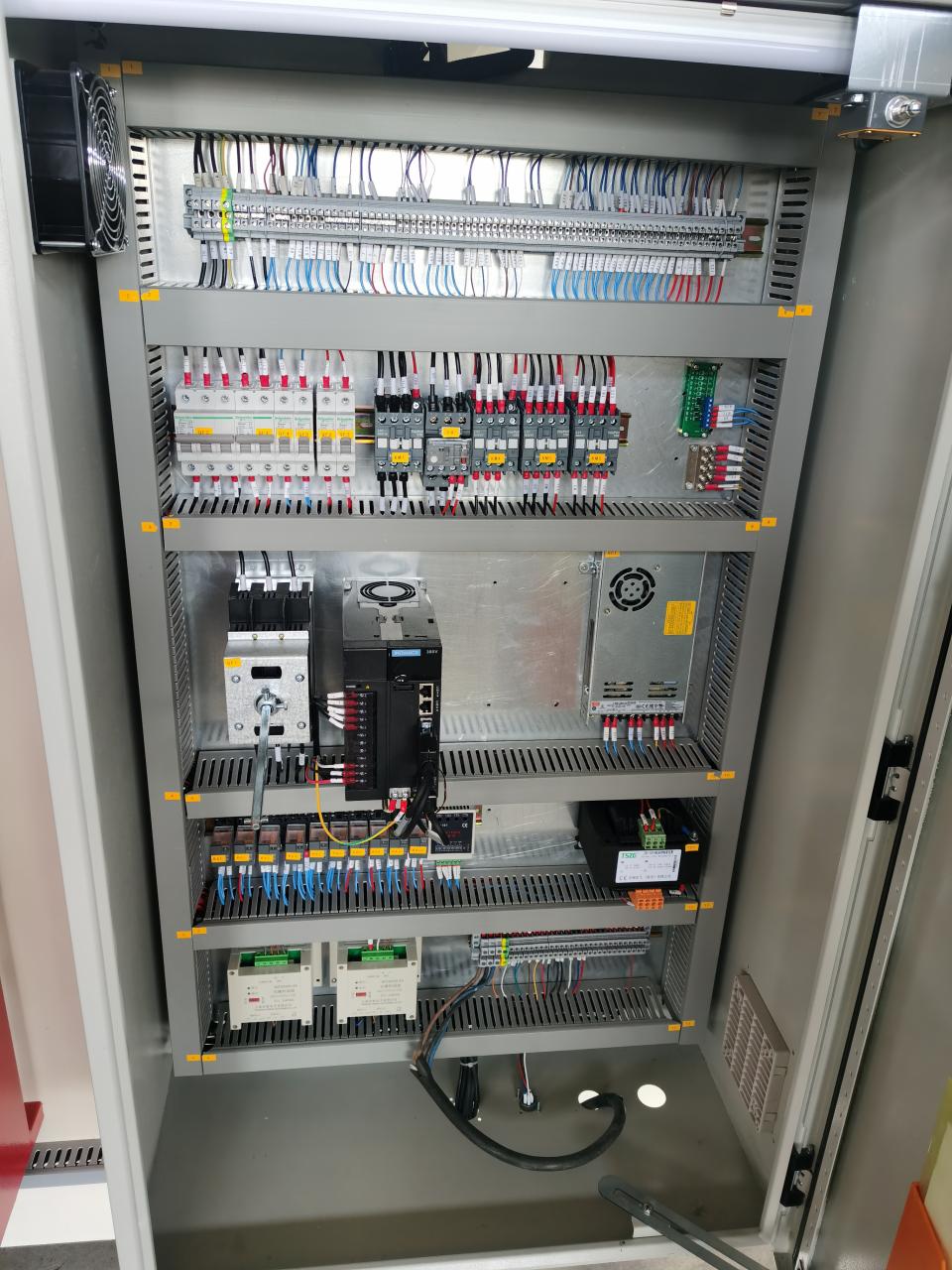

France Schneider Electrical component

1) Hydraulic automatic deflection compensation mechanism;

2) Ensure effective compensation without blind area;

3) High precision of bending and long stability.

Packing & Delivery

Normal package is plastic, for machine safety, we suggest that customers use wooden case for packaed machine.We can give you best and suitable shipment ways. We have a professional documentation department to help customers solve import problems and provide a complete set of customs clearance documents

FAQ

*We have our own factory and brand; Our machines can match all the CE standard or more strict ones.

*Quality assurance: 2 years warranty and 100% quality inspection before packing.

*Service: Impeccable after-sale service, and all your problem will be solved within 24 hours.

*Price: Can be negotiable according to the qty.

*MOQ: 1 set.

Details

- Slider Stroke (mm): 200 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 320 mm

- Machine Type: Synchronized, Press Brake

- Length of Working Table (mm): 3200 mm

- Width of Working Table (mm): 1600 mm

- Dimension: 3200*1600*2600 mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: End Forming

- Weight (KG): 6000

- Motor Power (kw): 11 kw

- Key Selling Points: High Safety Level

- Warranty: 1 Year

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Italy, Germany, Brazil, Peru, Saudi Arabia, Mexico, Russia, Kenya, Argentina, Chile, UAE, Colombia, Romania, Bangladesh, Kazakhstan, Uzbekistan, Tajikistan

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox, Other

- Usage: Metal Sheet Rolling Cutting Bending

- Model: cnc press brake

- Control system: DA-41,DA52S,DA66T,DA58T

- Raw Material: Steel Bar

- Name: CNC bending machine

- Color: Customized

- Mode: CNC

- Type: Metal Bender Tools

- Certification: ce