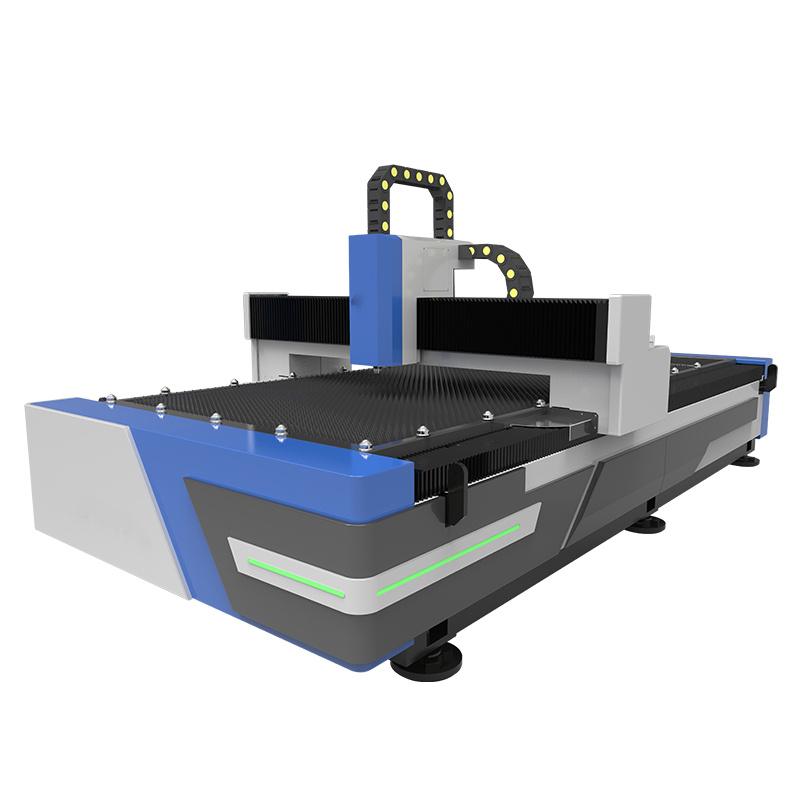

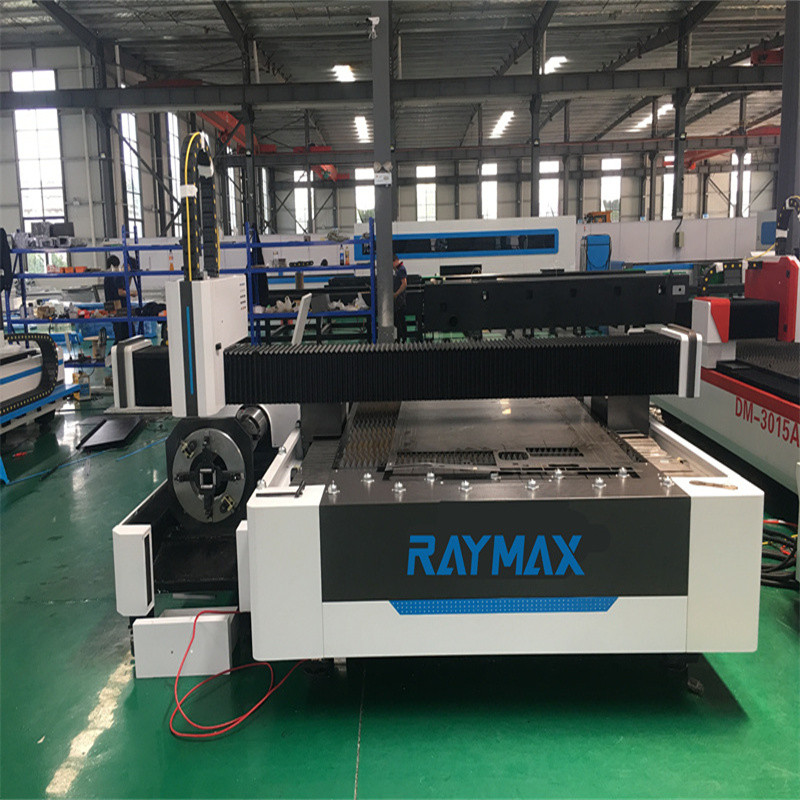

Laser Cutter Introduction

RAYMAX Laser cutting machine masters the core technology in laser cutting research and development, with fast cutting speed and high precision, suitable for cutting precision parts. In addition, it is not limited to the limitation of cutting patterns, automatic typesetting saves materials, the cut is smooth, the heat-affected zone is small, and it is not easy to deform. The cutting seam is smooth and beautiful, without subsequent processing. It is also equipped with high-quality configuration and professional quality service guarantee.

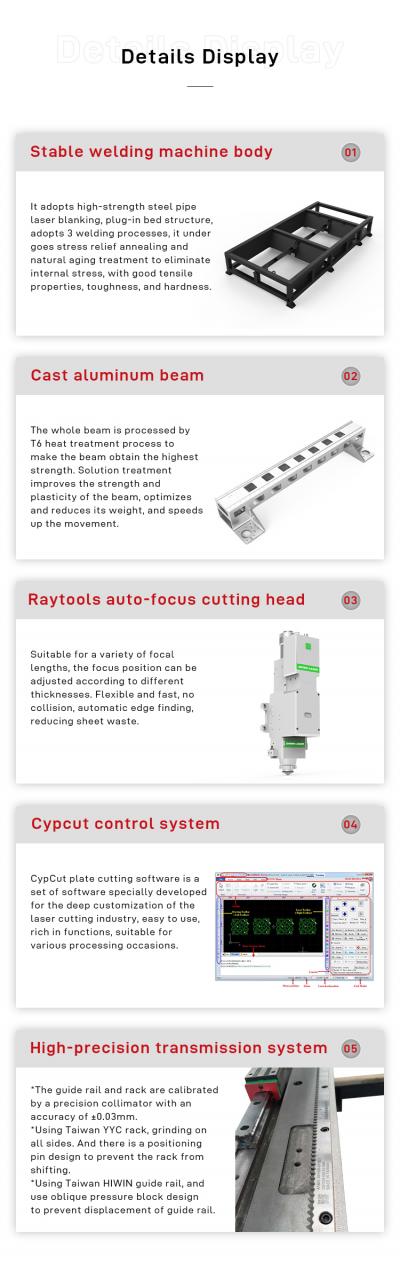

Laser Cutter Details

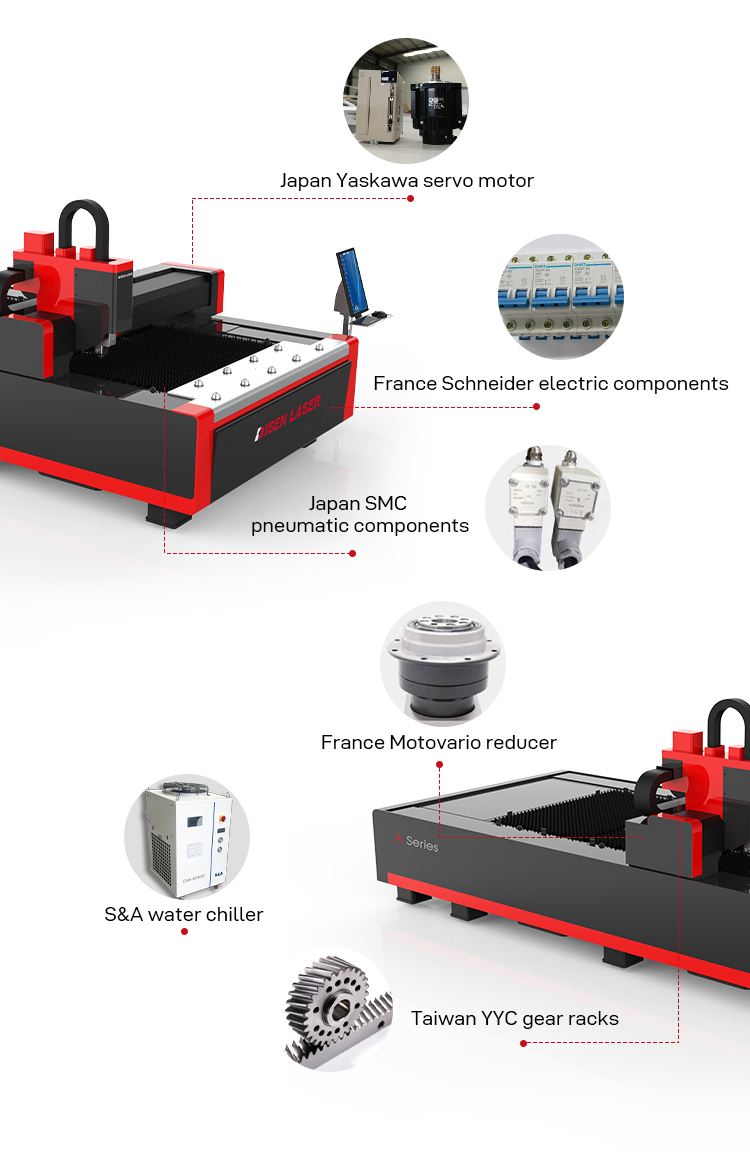

Configuration Description

RAYMAX Laser cutting machine has selected the best configuration based on cutting performance, product guarantee, and comparison of the same products. The configuration mainly includes the engine of Yaskawa, Japan, the electrical components of Schneider of France, and the reducer of Modoli. The machine itself is simple to maintain, safe and reliable, energy-saving and consumption-reducing, flexible in operation, and excellent in performance.

Laser Cutter Paramenters

| Laser Power | 1000W / 1500W |

| Laser Type | Fiber |

| Max. Linkage Speed | 45m/min |

| Z-axis Travel | 80mm |

| Worktable Load-bearing | 400kg |

| Positioning Accuracy | 0.05mm |

| Repositioning Accuracy | 0.03mm |

| Machine Size | 4500mm*2300mm*2000mm |

| Cooling System | Water Chiller |

| Function | Cutting Metal Materials |

The advantage of the Laser cutting machine lies in its own automatic lubrication system, which guarantees the convenience and smoothness of the cutting machine when using it. At the same time, it can provide circulating oil to avoid waste and can automatically maintain the equipment. In addition, its automatic follow-up system can be adjusted according to the difference between the plate and the source distance to ensure the integrity of the finished product.

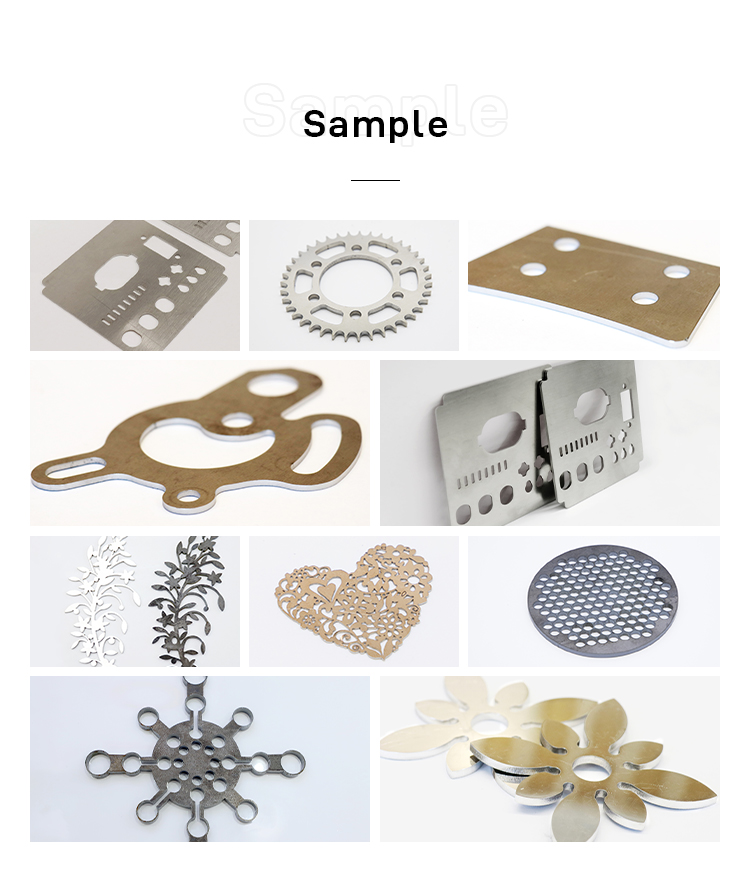

Application Area

The laser cutting machine has a wide range of applications, and can be used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, gifts and crafts, tool processing, decoration, Advertising, metal foreign trade processing and other manufacturing and processing industries. It is mainly suitable for cutting low carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel plate, pickling plate, aluminum zinc plate, copper and various metal materials.

Details

- Application: LASER CUTTING

- Applicable Material: Metal

- Condition: New

- Laser Type: Fiber Laser, Fiber

- Cutting Area: 1500mm*3000mm

- Cutting Speed: Depend on Laser power and Materials

- Graphic Format Supported: AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

- Cutting Thickness: 1-14mm carbon steel

- CNC or Not: Yes

- Cooling Mode: WATER COOLING

- Control Software: Cypcut

- Brand Name: RAYMAX Laser

- Laser Source Brand: MAX

- Laser Head Brand: Raytools

- Servo Motor Brand: Yaskawa

- Guiderail Brand: HIWIN

- Control System Brand: Cypcut

- Weight (KG): 1500 KG

- Key Selling Points: Competitive Price

- Warranty: 3 years

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 3 years

- Core Components: Laser Source

- Laser Power: 1000W / 1500W

- Z-axis Travel: 80mm

- Max. Linkage Speed: 45m/min

- Worktable Load-bearing: 400kg

- Positioning Accuracy: 0.05mm

- Repositioning Accuracy: 0.03mm

- Machine Size: 4500mm*2300mm*2000mm

- Function: Cutting Metal Materials

- Cooling System: Water Chiller

- Certification: ce

- After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service