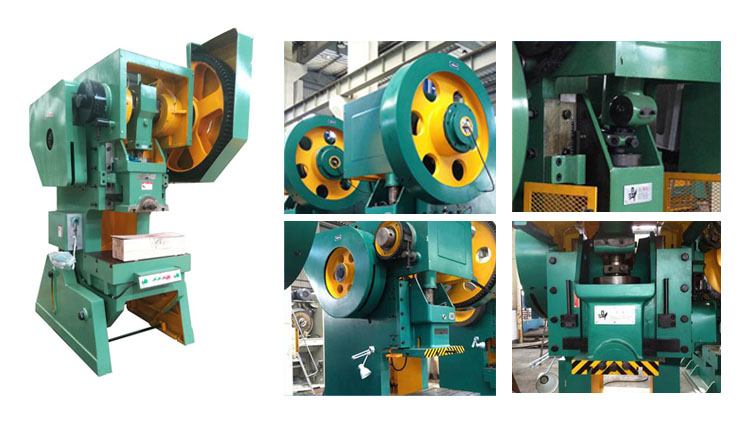

Products Description

Power press machine suitable for blanking, punching, forming, bending, stretching and other cold stamping process to achieve. Widely used in electrical appliances, vehicles, tractors, mining machinery, hardware tools, machinery manufacture and other industrial areas.

1. Steel plate welding machine, good rigidity, more stable accuracy.

2. Crankshaft longitudinal, compact structure, beautiful appearance.

3. Electric adjustment of the height of the mould, digital display control height.

4. Rectangular block with a lengthened guide, bronze lining board, high guidance accuracy.

5. Combined pneumatic friction clutch brake, joint stable, action sensitivity.

6. Collapse type safety device, to ensure the safety of the whole machine.

7. Slider is high, there is a lifting type balance cylinder, to achieve the balance of the slider bar.

8. The slider can be moved with a small movement, emergency stop motion, more secure operation.

9. The circuit uses double valve control, the action is nimble, accord with the safety standard of press.

Machine Part

Name: Machine Body

Original: ChinaUse rod tightening combination frame structure, with sufficient strength and rigidity;The slider uses rail guide; machine and slider are welded steel, the material is Q235-A, using carbon dioxide gas shielded arc welding, the weld should be ground smooth, no weld slag and streaming scars, remove inner stress after weld.

Name: Oil Cylinder

Original: China

Solo cylinder structure which is disposed on the upper beam hole, cylinder block uses 45 # forged steel.

Plunger rod surface hardening hardness is HRC45-50. The cylinder finishing by high-precision machine tools, cylinder bore after refining process to increase surface hardness and wear resistance.

Name: Bliwing Cylinder

Original: China

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F 4R sliding sleeve shift.

Name: Oil Cylinder

Original: China

Solo cylinder structure which is disposed on the upper beam hole, cylinder block uses 45 # forged steel.

Plunger rod surface hardening hardness is HRC45-50. The cylinder finishing by high-precision machine tools, cylinder bore after refining process to increase surface hardness and wear resistance.

Punches can be made into finished products

Product Paramenters

| SPECIFICATIONS FOR OPEN-TYPE TILTING POWER PRESS MACHINE | ||

| J23-10T J23-80T | Min. 100 KN | Max. 800 KN |

| Min. 4 mm | Max. 8 mm | |

| Min. 50 t/min | Max. 130 t/min | |

| J21-100T J21S-125T | Min. 100KN | Max. 1250 KN |

| Min. 4 mm | Max. 10 mm | |

| Min. 45 t/min | Max. 130 t/min | |

| Diameter of Blank-holding hole | Min. 100 mm | Max. 260 mm |

| Min. 180 mm | Max. 400 mm | |

| Min. 95 mm | Max. 210 mm | |

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas. Product packaging

FAQ

1. Does your company accept customized offer, we have special need.

RAYMAX is a company that focuses on research and manufacture of modular cnc machines. We have a very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

2. What certificate the machine in your company get?

We’ve passed the ISO9001 Quality System Approval and CE Certification.

3. Do you have price list for optional configuration?

We have various configurations and so many different specifications, so we can’t offer you price list. Please contact our sales engineer if you’re interested in certain specific configuration.

4. Does your company accept CIF price?

CIF price includes shipping cost of cnc machine which needs to quote according to the different destination port and various in different months. Please contact us when you have such need. CIF price also includes marine premium which is 2‰ of 1.1*total amount.

5. If your engineer come to our country to fix the machine and do some training, how much will it cost?

The cost mainly contain the cost of round-trip flight tickets, board and lodging as well as v isa fee. Staff cost is

100USD/day/person, normally, it’s a two person job. But it will depends for a large equipment or installation and debugging of the whole line.

6. What’s the warranty?

Warranty is 12 months which begins from the day when the machine has arrived at the importer’s port.

7. What’s your methods of transportation?

For most countries, we will transport our machine by sea, as for inland countries, we may use railway or highway transportation.Exported cnc machine is all be packed by wooden case which can be fixed into a 40 HQ.

8. If the machine is out-of-warranty, how to charge the cost of accessories?

For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

9. What I would do for the machine failure?

If the machine malfunction and users are unable to resolve, please email us for consultation. Our service department will respond within 24 hours.

10. How to define the machine warranty? When did you start timing?

We identify the warranty based on the factory number. Warranty timing counted starting after equipment commissioning and acceptance. If you have any questions, please email us for consultation.

11. How long is the warranty period of machine tool?

We commitment to client machines are one-year warranty. For the purchase of the user, registered as a member in this website,with the factory number of the machine, you can enjoy extended warranty of 3 months. For details, please refer to membership service.

12. Does RAYMAX have maintenance manual and operation manual?

Each cnc machine leaving the factory will be along with related series or model the English instructions including maintenance manual and operation manual. Attached documentations may also include cnc controller instruction, parts instruction you bought(like rotaty table, oil cooler)

Details

- CNC or Not: CNC

- Condition: New

- Machine Type: Punching Machine

- Power Source: Hydraulic

- Voltage: 380V/220V Optional

- Dimension(L*W*H): 3800mmx1900mmx1900mm

- Motor Power (kW): 4

- Weight (T): 5500

- Key Selling Points: Competitive Price

- Warranty: 1 Year

- Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Energy & Mining, Advertising Company

- Showroom Location: United States, Germany, Brazil, Peru, Pakistan, India, Mexico, Spain, Thailand, Morocco, Kenya, South Korea, Chile

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Gearbox, PLC

- After-sales Service Provided: Engineers available to service machinery overseas

- Power: 7.5KW

- Weight: 1-6T

- Application: Metal Sheet Stamping

- Function: Steel Metal Punching

- Type: J23-25 Ton Power Press

- Keyword: Mechanical Metal Punching Machine

- Crank: Single Crank Press

- Processing material: Stainless Stee

- Purpose: Shape Hole

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: Italy, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Australia, Argentina, South Korea, Chile, UAE, Colombia, Sri Lanka, Romania, Bangladesh, Kazakhstan

- Certification: CE ISO