Products Description

The guillotine shear is the fruit of a project resulting in our bringing together ‘Made in China’ creativity, design and innovation with all the reliability of the best Chinese and European component range.The result is a perfect mix of avant-garde and efficient technology, guarantee of an extremely solid machine, precise with its cuts and of extremely high quality.

Machine Design

RAYMAX Shears features a rigid frame for min deflection under the load. The frame steels are German origin and designed using SOLIDWORKS 3D programming and made with quality steel Improved Q235 using the latest technology.

Feature:

* The machine welding is made by welding plant and welding robots.

* After the welding,we make stress relief process by vibration system.

* After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy.

* Allreference surfaces and connection holes are machined.

Shearing Process

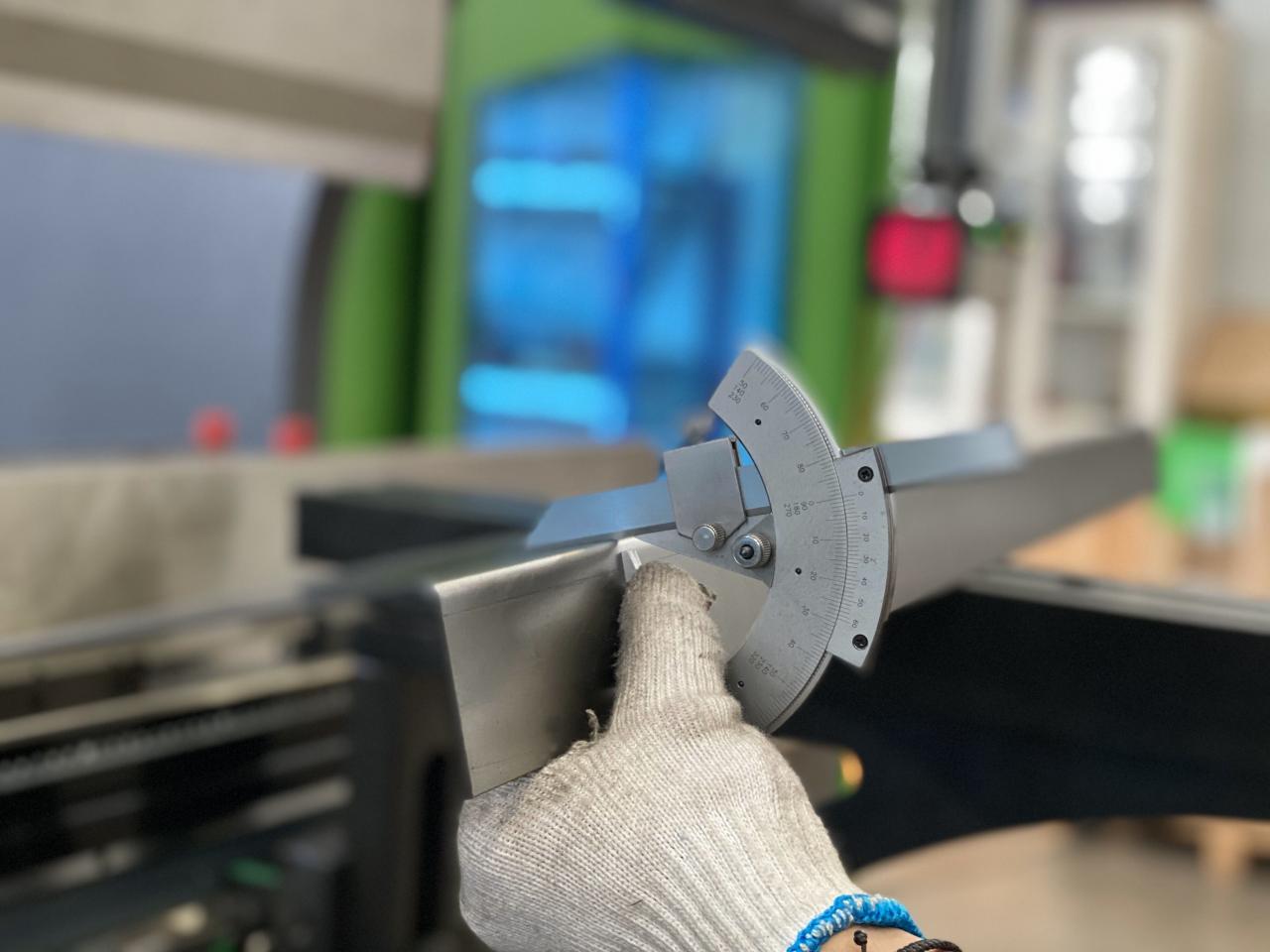

Perfect design in every aspect; By choosing the new and improved CNC Master MS8 guillotine, you will bring modern-day technology to your company with maximum safety, high accuracy and unique ease of use. Blade gap, cutting angle and cutting length are all adjusted based on material selection and thickness automatically.

Quality

RAYMAX, known as one of the top worldwide manufacturers in the sheet metal industry, proudly announces its latest shear model to the market,Variable Rake Hydraulic Guillotine. The critical parts of the Accurl press brakes are manufactured in Germany.The carefully selected components come from long-term partners. We rely on our quality and therefore give our guillotine a 3-year warranty.

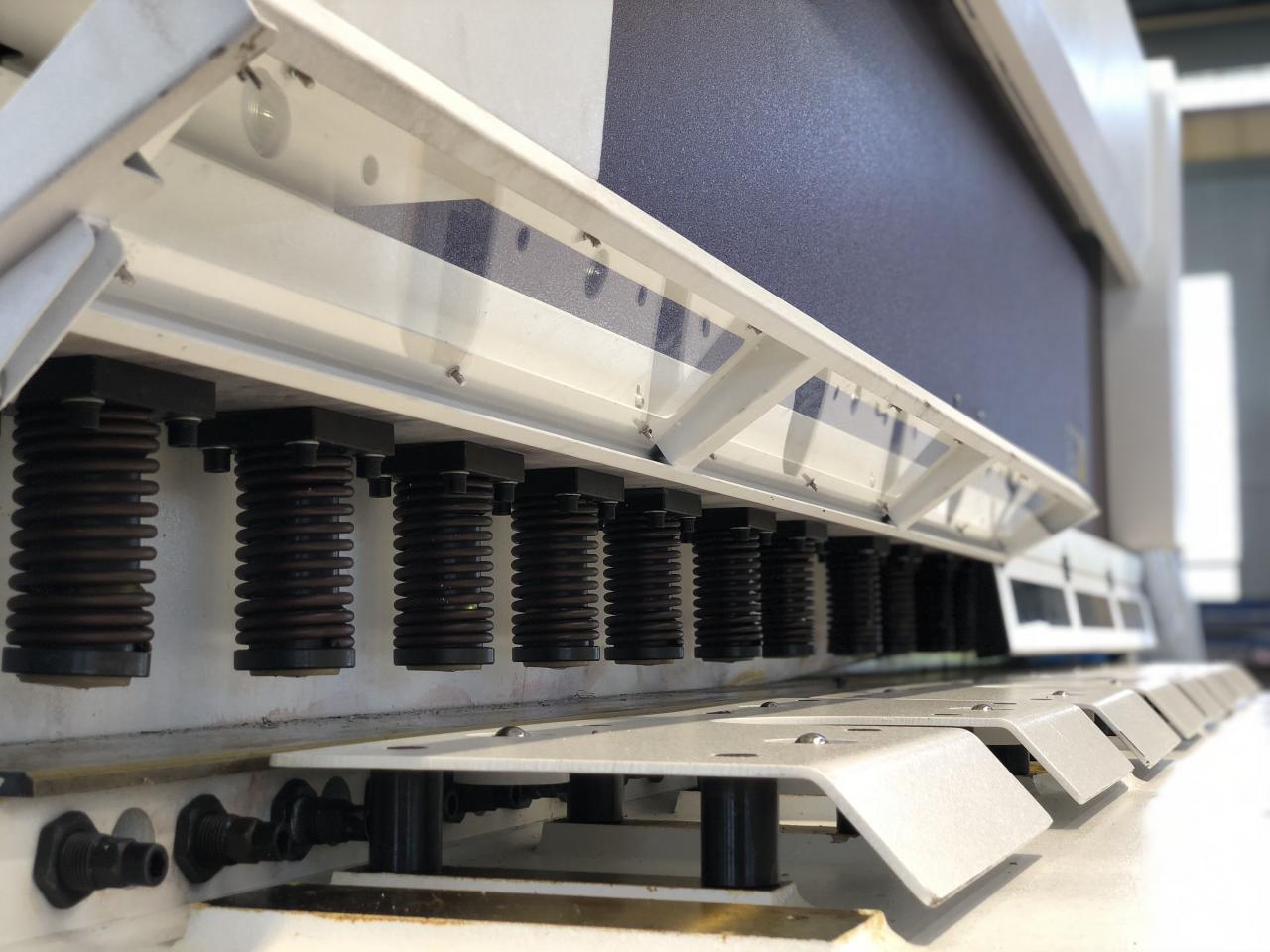

Pneumatic Sheet Support System

Pneumatic Sheet Support System

Monobloc Panel Type support system: Avoids hanging down the wide and thin sheets via pneumatic table support and provides more precise cuts.

Cnc Control Unit

* 7" widescreen TFT Colour LCD display

* Back / front gauge control

* Panel based housing

* Retract function

* Cutting angle and gap control

* Stroke length limitation

* Manual movement of all axes

* Force control

* Return to Sender function

* Program memory for 100 programs

* Sheet support system.

DAC360T CNC Control Unit

RAYMAX has chosen the very powerful new generation DELEM DAC360T offers an higher level of efficiency in programming and control of guillotine. The winning MADE in Netherlands design and the high quality of all the construction details, guarantee prestigious performances and long product life.

Specification

| Type | Cut Thicknessmm | Cut lengthmm | Shear AngleDegree | SPMmin-1 | Back Gaugemm | Throat Depthmm | Main Motorkw | Net Weightkg |

| MS8-6×3200 | 6 | 3200 | 0.5°-1.5° | 14 | 800 | 100 | 7.5 | 6500 |

| MS8-6x4000 | 6 | 4000 | 0.5°-1.5° | 12 | 800 | 100 | 7.5 | 8400 |

| MS8-8×3200 | 8 | 3200 | 0.5°-1.5° | 12 | 800 | 100 | 7.5 | 7400 |

| MS8-8x4000 | 8 | 4000 | 0.5°-2.0° | 11 | 800 | 100 | 11 | 9500 |

| MS8-10×3200 | 10 | 3200 | 0.5°-2.0° | 8 | 800 | 120 | 11 | 8500 |

| MS8-10x4000 | 10 | 4000 | 0.5°-2.0° | 8 | 800 | 120 | 11 | 11000 |

| MS8-13×3200 | 13 | 3200 | 0.5°-2.0° | 7 | 800 | 120 | 18.5 | 9200 |

| MS8-13×4000 | 13 | 4000 | 0.5°-2.2° | 6 | 800 | 130 | 18.5 | 12800 |

| MS8-13×6000 | 13 | 6000 | 0.5°-2.4° | 6 | 1000 | 150 | 18.5 | 26000 |

| MS8-16×3200 | 16 | 3200 | 0.5°-2.5° | 6 | 800 | 130 | 22 | 12000 |

| MS8-16×4000 | 16 | 4000 | 0.5°-2.5° | 6 | 1000 | 130 | 30 | 26500 |

| MS8-16×6000 | 16 | 6000 | 0.5°-2.5° | 6 | 1000 | 130 | 30 | 33000 |

| MS8-16×8000 | 12 | 4000 | 0.5°-2.5° | 5 | 1000 | 130 | 30 | 75500 |

Product packaging

1. Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

1. Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3. The outmost is wooden case with fixed formwork.

4. The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our Serives

FAQ

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

2. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In

all cases we will try to accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4. What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6. How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Details

- Max. Cutting Width (mm): 6000 mm

- Max. Cutting Thickness (mm): 16 mm

- Automatic Level: Fully Automatic

- Shearing Angle: 0.5°-2.5°

- Blade Length (mm): 6000 mm

- Backgauge Travel (mm): 20 - 1000 mm

- Throat Depth (mm): 130 mm

- Condition: New

- Brand Name: RAYMAX

- Power (kW): 30 kW

- Weight (KG): 30000 KG

- Place of Origin: Anhui, China

- Voltage: 220V/380V

- Dimension(L*W*H): 7100*2300*2950mm

- Year: 2020

- Warranty: 3 years

- Key Selling Points: Competitive Price

- Applicable Industries: Building Material Shops, Machinery Repair Shops

- Showroom Location: United Kingdom, United States, South Africa

- Marketing Type: Hot Product 2019

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 3 years

- Core Components: Pump

- After-sales Service Provided: Engineers available to service machinery overseas, Online support, Video technical support

- Control system: Accurl Estun E21s NC Control

- Main Motor: Siemens from Germany Brand

- Tubing connector: EMB form Germany Brand

- Hydraulic System: Bosch-Rexroth form Germany

- Name: Hydraulic Guillotine Shears

- Cutting material: Metal Stainless Steel Carbon Steel

- Color: Customer Requirement

- Keyword: Hydrualic Shearing Machine

- Cutting mode: Cold Cutting

- After Warranty Service: Video technical support, Online support

- Local Service Location: United Kingdom, United States, Sri Lanka

- Certification: CE ISO