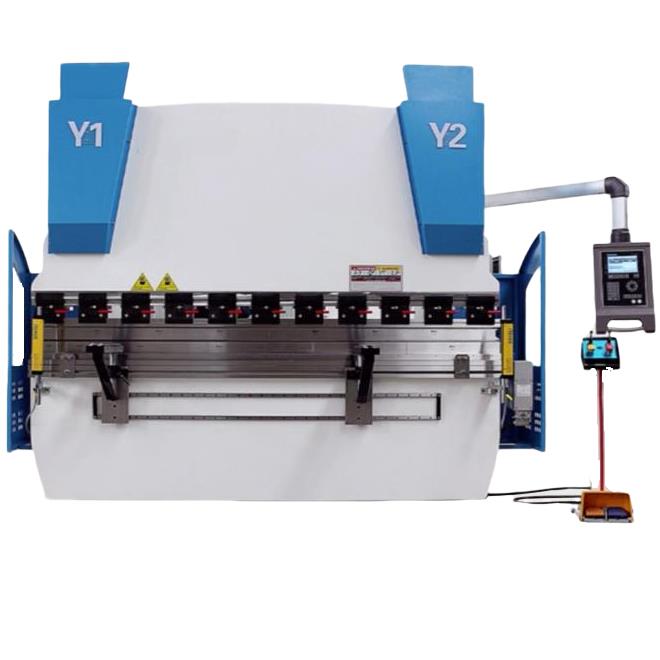

Press Brake/Bending Machine

hydraulic press brake cnc bending machine with precision backgauge, servo motor,safety protection, fast clamp, ball screw and linear guide. All from Germany, USA, Holland, Italy Brand parts.The bend thickness and length can be manufactured customized.

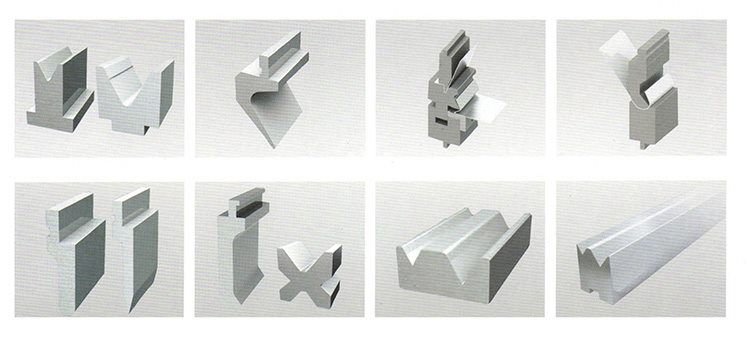

Cuttable graphics

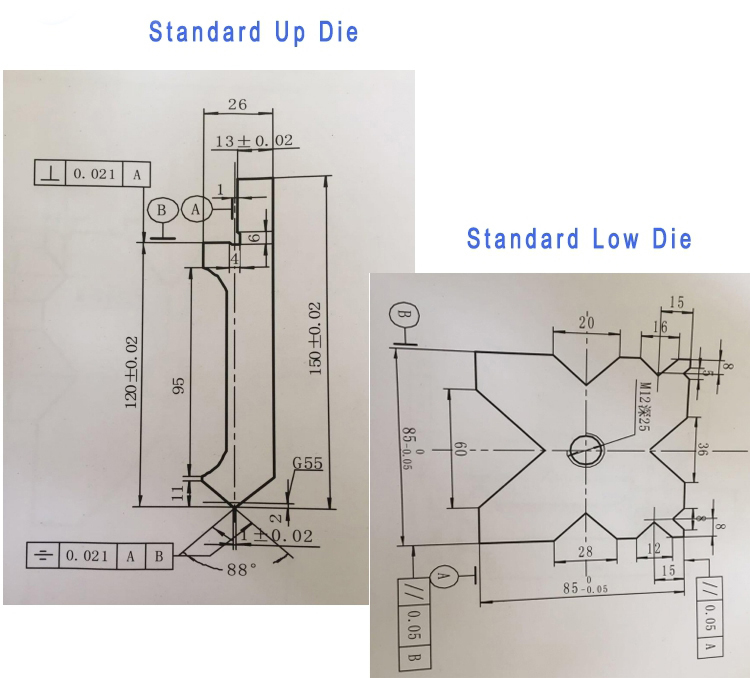

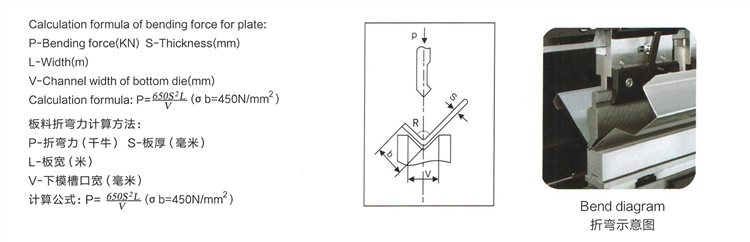

Force Chart for Press Brake

WC67Y/K press brake

WC67Y/K press brake

●Servo motor control

●Store up to 100 programs

●Up to 25 bends per program

●Tool library & Tool program

●Automatic Bending angle program

●Higer ram and backgahge speed

●Higer bending and positioning accuracy

WC 67Y/K Features

The whole welded machine structure achieves high rigidity; the machine is designed by ANSYS software which can ensure the reliability and precision of the press brake.

The motors for backgauge are controlled by inverter, which can achieve high positioning accuracy of the backguage and ram by changing the frequency and voltage of motor.

Different punch and dies are optional according to customer' s requirements,such as Multi-V die,radius die,gooseneck die, etc.One set of complete standard punch and die will be included for free.

X axis(Backgahge) and Y axis(Ram stroke or cylinder stroke) can be programmed by E21 system controller,which can store up to 40 groups of programs.Side and rear metal safety guard meets European safety standard.

Hydraulic overload can be protected by overflow valve,System pressure can be regulated by pressure switch easily.

Foot switch with emergency button can stop the machine immediately when accident happens.

| Type | Nominal Pressure | Worktable Length | Column spacing | Throat Depth | Slide Stroke | Max Open | Motor Power | Dimensions |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

| WC67Y- 40t/2200 | 400 | 2200 | 1775 | 250 | 100 | 320 | 5.5 | 2300×1500×2000 |

| WC67Y- 40t/2500 | 400 | 2500 | 1975 | 250 | 100 | 320 | 5.5 | 2600×1500×2000 |

| WC67Y- 63t/2500 | 630 | 2500 | 2095 | 250 | 120 | 360 | 5.5 | 2600×1600×2300 |

| WC67Y- 63t/3200 | 630 | 3200 | 2570 | 250 | 120 | 360 | 5.5 | 3300×1600×2300 |

| WC67Y- 80t/3200 | 800 | 3200 | 2565 | 320 | 120 | 360 | 7.5 | 3300×1700×2300 |

| WC67Y- 80t/4000 | 800 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1700×2300 |

| WC67Y- 100t/3200 | 1000 | 3200 | 2560 | 320 | 120 | 360 | 7.5 | 3300×1800×2400 |

| WC67Y- 100t/4000 | 1000 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1800×2500 |

| WC67Y- 125t/3200 | 1250 | 3200 | 2550 | 320 | 120 | 360 | 7.5 | 3250×1920×2450 |

| WC67Y- 125t/4000 | 1250 | 4000 | 3450 | 320 | 120 | 360 | 7.5 | 4100×1920×2500 |

| WC67Y- 160t/3200 | 1600 | 3200 | 2540 | 320 | 180 | 440 | 11 | 3300×1600×2600 |

| WC67Y- 160t/4000 | 1600 | 4000 | 3140 | 320 | 180 | 440 | 11 | 4100×2000×2600 |

| WC67Y- 160t/6000 | 1600 | 6000 | 4740 | 320 | 180 | 440 | 11 | 6100×2000×2600 |

| WC67Y- 200t/3200 | 2000 | 3200 | 2540 | 320 | 250 | 530 | 11 | 3300×2100×2800 |

| WC67Y- 200t/4000 | 2000 | 4000 | 3140 | 320 | 250 | 530 | 15 | 4100×2100×2900 |

| WC67Y- 200t/5000 | 2500 | 5000 | 3120 | 400 | 250 | 530 | 15 | 5100×2100×3000 |

| WC67Y- 250t/4000 | 2500 | 4000 | 3120 | 400 | 250 | 560 | 18.5 | 4100×2200×3500 |

| WC67Y- 250t/5000 | 2500 | 5000 | 3920 | 400 | 250 | 560 | 18.5 | 5100×2200×3500 |

| WC67Y- 250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

| WC67Y- 300t/5000 | 3000 | 5000 | 39100 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

| WC67Y- 300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

| WC67Y- 300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

| WC67Y- 350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

| WC67Y- 350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

| WC67Y- 400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

| WC67Y- 400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

| WC67Y- 500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

| WC67Y- 500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

| WC67Y- 500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

| WC67Y- 600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

| WC67Y- 600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

WE67K Series Electro-hydraulic Servo Press Brake CNC Bending Machine

WE67K Series Electro-hydraulic Servo Press Brake CNC Bending Machine adopts integral welding and integral processing structure.

The main components of the body are analyzed with ANSYS finite element analysis software, which ensures the reliability and

overall accuracy of the machine tool.

The main oil cylinder on both sides breaks through the stroke control mode of the traditional mechanical baffle type bending

machine and adopts the closed-loop control mode consisting of the electro-hydraulic servo valve imported from Germany and thegrating ruler imported from Germany.

WE67YK Features

●Advanced Configuration,high precision and high eficiency CNC hydraulic press brake

●Holistic welding structure

●Electro-hydraulic servo system,the closed-loop cotrol the slider synchronization

●Double crowning mechanism

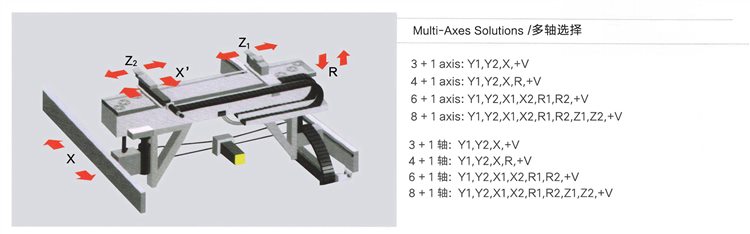

●Standard configuration with 3 1axes:

Y1(upward-downward of left cylinder)

Y2(upward-downward of right cylinder)

X(forward-backward of backguge)

V(hydraulic crowning)

●Backgauge System Optional:

4axes Backgauge(X. R,Z1. Z2)

5axes Backgauge(X. R. Z1. Z2,X')

6axes Backgauge(X1. X2. R1. R2,Z1. Z2)

| Type | Nominal Pressure | Worktable Length | Column spacing | Throat Depth | Slide Stroke | Max Open | Motor Power | Dimensions |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

| WE67K-40t/2200 | 400 | 2200 | 1775 | 250 | 175 | 320 | 5.5 | 2300×1500×2000 |

| WE67K-40t/2500 | 400 | 2500 | 1975 | 250 | 175 | 320 | 5.5 | 2600×1500×2000 |

| WE67K-63t/2500 | 630 | 2500 | 2095 | 250 | 175 | 360 | 5.5 | 2600×1600×2300 |

| WE67K-63t/3200 | 630 | 3200 | 2570 | 250 | 175 | 360 | 5.5 | 3300×1600×2300 |

| WE67K-80t/3200 | 800 | 3200 | 2565 | 320 | 175 | 360 | 7.5 | 3300×1700×2300 |

| WE67K-80t/4000 | 800 | 4000 | 3165 | 320 | 175 | 360 | 7.5 | 4100×1700×2300 |

| WE67K-100t/3200 | 1000 | 3200 | 2560 | 320 | 215 | 360 | 7.5 | 3300×1800×2400 |

| WE67K-100t/4000 | 1000 | 4000 | 3165 | 320 | 215 | 360 | 7.5 | 4100×1800×2500 |

| WE67K-125t/3200 | 1250 | 3200 | 2550 | 320 | 215 | 360 | 7.5 | 3250×1920×2450 |

| WE67K-125t/4000 | 1250 | 4000 | 3450 | 320 | 215 | 360 | 7.5 | 4100×1920×2500 |

| WE67K-160t/3200 | 1600 | 3200 | 2540 | 320 | 215 | 440 | 11 | 3300×1600×2600 |

| WE67K-160t/4000 | 1600 | 4000 | 3140 | 320 | 215 | 440 | 11 | 4100×2000×2600 |

| WE67K-160t/6000 | 1600 | 6000 | 4740 | 320 | 215 | 440 | 11 | 6100×2000×2600 |

| WE67K-200t/3200 | 2000 | 3200 | 2540 | 320 | 215 | 530 | 11 | 3300×2100×2800 |

| WE67K-200t/4000 | 2000 | 4000 | 3140 | 320 | 215 | 530 | 15 | 4100×2100×2900 |

| WE67K-200t/5000 | 2500 | 5000 | 3120 | 400 | 215 | 530 | 15 | 5100×2100×3000 |

| WE67K-250t/4000 | 2500 | 4000 | 3120 | 400 | 215 | 560 | 18.5 | 4100×2200×3500 |

| WE67K-250t/5000 | 2500 | 5000 | 3920 | 400 | 215 | 560 | 18.5 | 5100×2200×3500 |

| WE67K-250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

| WE67K-300t/5000 | 3000 | 5000 | 39100 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

| WE67K-300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

| WE67K-300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

| WE67K-350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

| WE67K-350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

| WE67K-400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

| WE67K-400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

| WE67K-500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

| WE67K-500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

| WE67K-500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

| WE67K-600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

| WE67K-600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

Double press brake

Two (WC67Y/WE67K) mainframes were selected to configure the dual-machine linkage synchronous equipment.

The double-machine combined bending machine can process super long workpiece, especially suitable for city construction, highway light pole, electric pole and so on.

The two types of machine tools can also be used separately to improve production efficiency and are equipped with a deflection

compensation mechanism.

The synchronous mechanism adopts mechanical liquid servo and mechanical block. ●This machine was combined by two sets of 400 tons press brake.

Tandem control achieve synchronous working. Single machine was combined by working table , right and left wall board.

Due to the transportation, we adopt assembled structure. The rack has strong rigidity, two cylinders were installed on right and left wall board, hydraulic system was under the action of electrical system, drive ram working down. On the ram, there are upper dies, when upper dies and lower dies touched, system will raise pressure and forming the workpieces.

With different dies and under different bending types, it can get different shapes of workpieces. The quality is stable and

reliable.

| Type | Nominal Pressure | Worktable Length | Column spacing | Throat Depth | Slide Stroke | Max Open |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| WE67K-500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 |

| WE67K-500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 |

| WE67K-500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 |

| WE67K-600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 |

| WE67K-600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 |

| WE67K-700t/8000 | 7000 | 8000 | 5300 | 400 | 320 | 630 |

| WE67K-700t/10000 | 7000 | 10000 | 5300 | 400 | 320 | 630 |

| WE67K-800t/8000 | 8000 | 8000 | 5300 | 400 | 320 | 630 |

| WE67K-1000t/10000 | 10000 | 10000 | 5300 | 400 | 320 | 630 |

| WE67K-1000t/12000 | 10000 | 12000 | 5300 | 400 | 320 | 630 |

| WE67K-1200t/12000 | 12000 | 12000 | 5300 | 400 | 320 | 630 |

| WE67K-1200t/14000 | 12000 | 8600 | 5300 | 400 | 320 | 630 |

FAQ

1. Does your company accept customized offer, we have special need.

RAYMAX is a company that focuses on research and manufacture of modular cnc machines. We have a very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

2. What certificate the machine in your company get?

We’ve passed the ISO9001 Quality System Approval and CE Certification.

3. Do you have price list for optional configuration?

We have various configurations and so many different specifications, so we can’t offer you price list. Please contact our sales engineer if you’re interested in certain specific configuration.

4. Does your company accept CIF price?

CIF price includes shipping cost of cnc machine which needs to quote according to the different destination port and various in different months. Please contact us when you have such need.CIF price also includes marine premium which is 2‰ of 1.1*total amount.

5. If your engineer come to our country to fix the machine and do some training, how much will it cost?

The cost mainly contain the cost of round-trip flight tickets, board and lodging as well as v isa fee. Staff cost is

100USD/day/person, normally, it’s a two person job. But it will depends for a large equipment or installation and debugging of the whole line.

6. What’s the warranty?

Warranty is 12 months which begins from the day when the machine has arrived at the importer’s port.

7. What’s your methods of transportation?

For most countries, we will transport our machine by sea, as for inland countries, we may use railway or highway transportation. Exported cnc machine is all be packed by wooden case which can be fixed into a 40 HQ.

8. If the machine is out-of-warranty, how to charge the cost of accessories?

For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

9. What I would do for the machine failure?

If the machine malfunction and users are unable to resolve, please email us for consultation. Our service department will respond within 24 hours.

10. How to define the machine warranty? When did you start timing?

We identify the warranty based on the factory number. Warranty timing counted starting after equipment commissioning and acceptance. If you have any questions, please email us for consultation.

11. How long is the warranty period of machine tool?

We commitment to client machines are one-year warranty. For the purchase of the user, registered as a member in this website,with the factory number of the machine, you can enjoy extended warranty of 3 months. For details, please refer to membership service.

12. Does MC have maintenance manual and operation manual?

Each cnc machine leaving the factory will be along with related series or model the English instructions including maintenance manual and operation manual. Attached documentations may also include cnc controller instruction, parts instruction you bought(like rotaty table, oil cooler)

Details

- Slider Stroke (mm): 320 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 450 mm

- Machine Type: Torsion Bar, Beading Machine

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 400 mm

- Dimension: 6060*3100*3800mm

- Condition: New

- Material / Metal Processed: Stainless Steel

- Automation: Automatic

- Extra Services: Cut To Length

- Year: 2021

- Weight (KG): 1850

- Motor Power (kw): 37 kw

- Key Selling Points: Automatic

- Warranty: 1 Year

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

- Showroom Location: United States, Germany, Viet Nam, Brazil, Peru, Mexico, Russia, Thailand, Morocco, Kenya, Chile, Algeria, South Africa

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Raw Material: Steel Bar

- Power: Hydraulic

- Usage: Metal Sheet Bending

- Voltage: 220V/380V/400V

- Processing material: Steel Aluminum

- Using: Square steel I-beam ect.

- Material Processed: Mild Steel Sheet Plate bending

- Materials: Aluminum plate bending

- Certification: ISO 9001:2000

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service